Carbon Storage Atlas

- Why this Location

- Main Research Q&As Discovered

- Lessons Learned

- Field Site Story of Interest

- Geologic Details

- Sites

Lat/Long

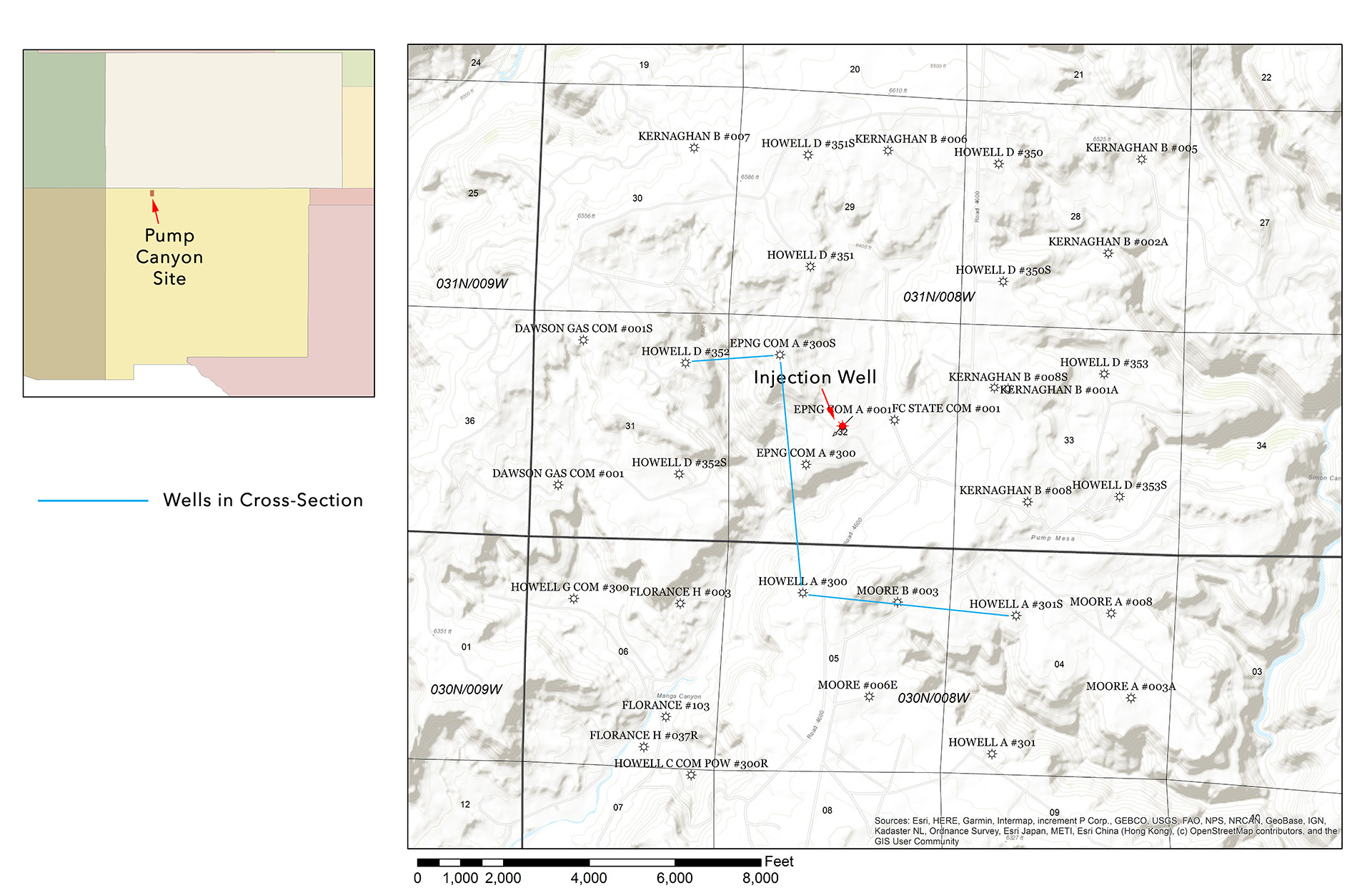

The Pump Canyon project site is in Section 32, T31N, R8W, New Mexico. (lat/long 36.867 / -107.631)

Map showing location of the San Juan Basin enhanced coalbed methane (ECBM) project (Pump Canyon), as well as the other two enhanced oil recovery (EOR) projects for the Southwest Regional Partnership on Carbon Sequestration’s (SWP) Phase II work. Note that the San Juan Basin terrestrial storage project site was also very close to the Pump Canyon site.

Why this Location

The original intent of the Pump Canyon project was to demonstrate effectiveness of carbon dioxide (CO2) storage in deep unmineable coal seams. The site is located in San Juan County, northern New Mexico, just within the limits of the high-permeability fairway of prolific coalbed methane production in the San Juan Basin (SJB). The SJB was assessed by Advanced Resources International (ARI) as one of the nation’s top coal basins for storage in terms of potential storage capacity (12 billion metric tons of CO2, 12% of U.S. total), enhanced coalbed methane (ECBM) potential (16 TCF, 10% of U.S. total), and potential cost of storage (at a predicted net profit of approximately $4-8/metric ton of CO2). The Pump Canyon location was favorable because of close proximity to Kinder Morgan’s Cortez pipeline transporting CO2 from McElmo Dome to the Permian Basin of West Texas, so infrastructure needs were minimized, requiring only an approximately 4.2-kilometer (2.6-mile) pipeline extension. The SJB could be a premier storage site, but many questions remained about the viability of ECBM and the project conducted at this location sought to answer some of those questions.

Main Research Q&As Discovered

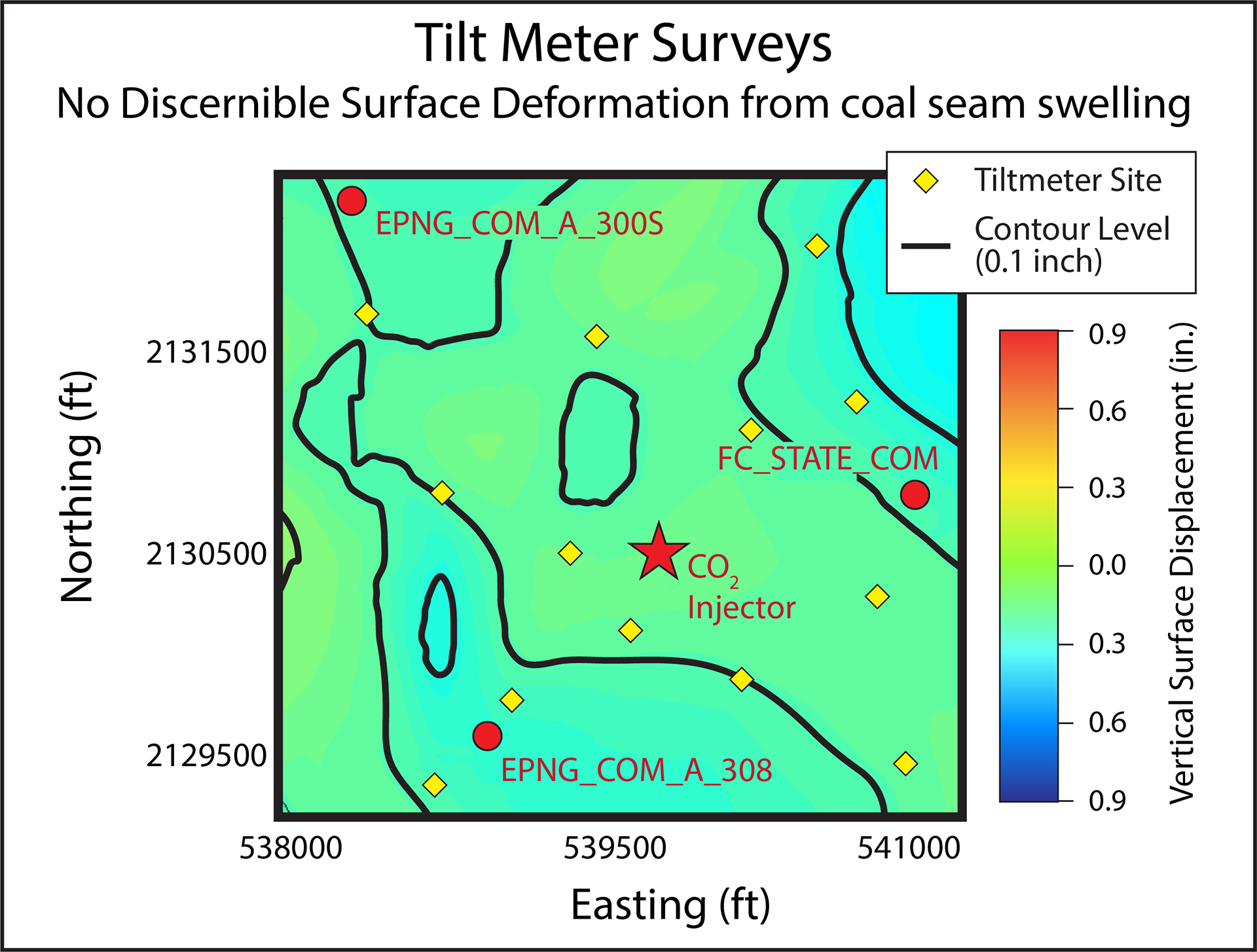

The major question addressed by this project was: can carbon dioxide (CO2) be stored in coal formations, and can it be done safely and economically? Due to the tendency of coal to swell when in contact with CO2, high initial permeability is needed to maintain high CO2 injection rates over time. Maintaining high injectivity is an important requirement for large-scale, low-cost CO2 storage in coal, and demonstrating this was an important goal of the U.S. Department of Energy’s (DOE) Carbon Storage Program. Coals in the San Juan Basin (SJB) fairway have exceptionally high permeability, and would represent one of the best places to demonstrate the viability of the technology. One concern unique to this project over the other Phase II sites was the possibility of surface deformation due to coal swelling in the presence of CO2. To monitor and measure any deformation, a unique network of 36 highly sensitive tiltmeters and Global Positioning System (GPS) stations were designed and installed by Pinnacle Technologies. Ultimately, the answers were that at least for this test design, injectivity was too great a hurdle, and while the tiltmeters demonstrated sensitivity, they did not detect any positive surface deformation.

Lessons Learned

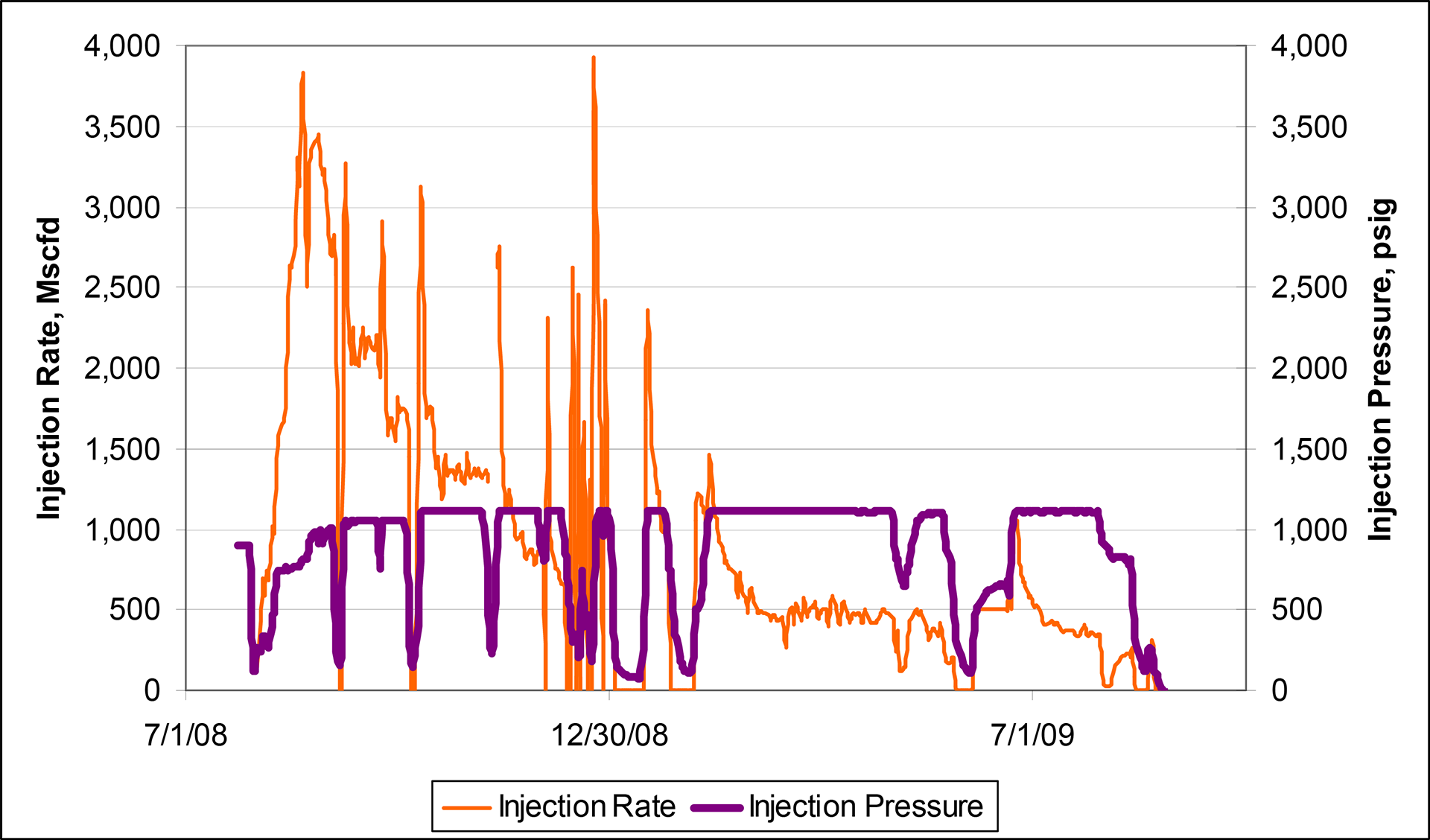

One major lesson was that while enhanced coalbed methane (ECBM) may be a viable technology in increasing methane production, swelling of coals can dramatically slow injection rates and this issue must be overcome before coal could be considered as a serious target for storage. During the course of the one-year project, the initial target injection rate of 1.25 cubic meters/second (m3/s) (3,800 thousand standard cubic feet per day [Mscfd])was reached, but was unsustainable for any length of time, dropping precipitously from 1.15 m3/s (3,500 Mscfd) to 0.08 m3/s (250 Mscfd) over the period.

A total volume of 13,503.445 metric tons of CO2 (14,885 tons) was injected, which was about one-quarter of the amount that was anticipated. Methane production was enhanced, with a likely additional approximately 736 thousand cubic meters (26 MMscf) coming from the carbon dioxide (CO2) injection; however, <1% would not provide sufficient economic incentive. The GPS/tiltmeter array monitoring and analysis showed no significant cumulative surface uplift due to CO2 injection; in fact, subsidence was the observed behavior.

This may be due to insufficient CO2 injected and the presence of nearby wells producing from the Fruitland coal, as well as the Mesaverde formation. Results definitely steered the Phase III project away from further pursuit of storage in coal seams.

Story of Interest

One of the stories from this area was how working both with the constraints of an operational gas field and in an area with numerous archeological sites and tribal entities led to challenges. Because one of the nearby field operators was concerned about carbon dioxide (CO2) breakthrough in their coalbed methane (CBM) wells, the site was moved several times. This incurred more expense in both the amount paid for the pipeline extension and in the setting out of some monitor equipment and doing some initial site survey work multiple times. Compliance with the National Historic Preservation Act also caused some project delays. Seven tribes had to be consulted, as well as the State Historic Preservation Office. Although the delays were only a few months, they affected the field operation of the rest of the project. Carbon dioxide was initially to be injected in a staged fashion into three layers, starting with the basal layer, in part to mitigate CO2 breakthrough into offset gas wells. Time constraints then dictated that all three layers were injected simultaneously to attempt to inject the volume the demonstration had been designed for.

Geologic Details

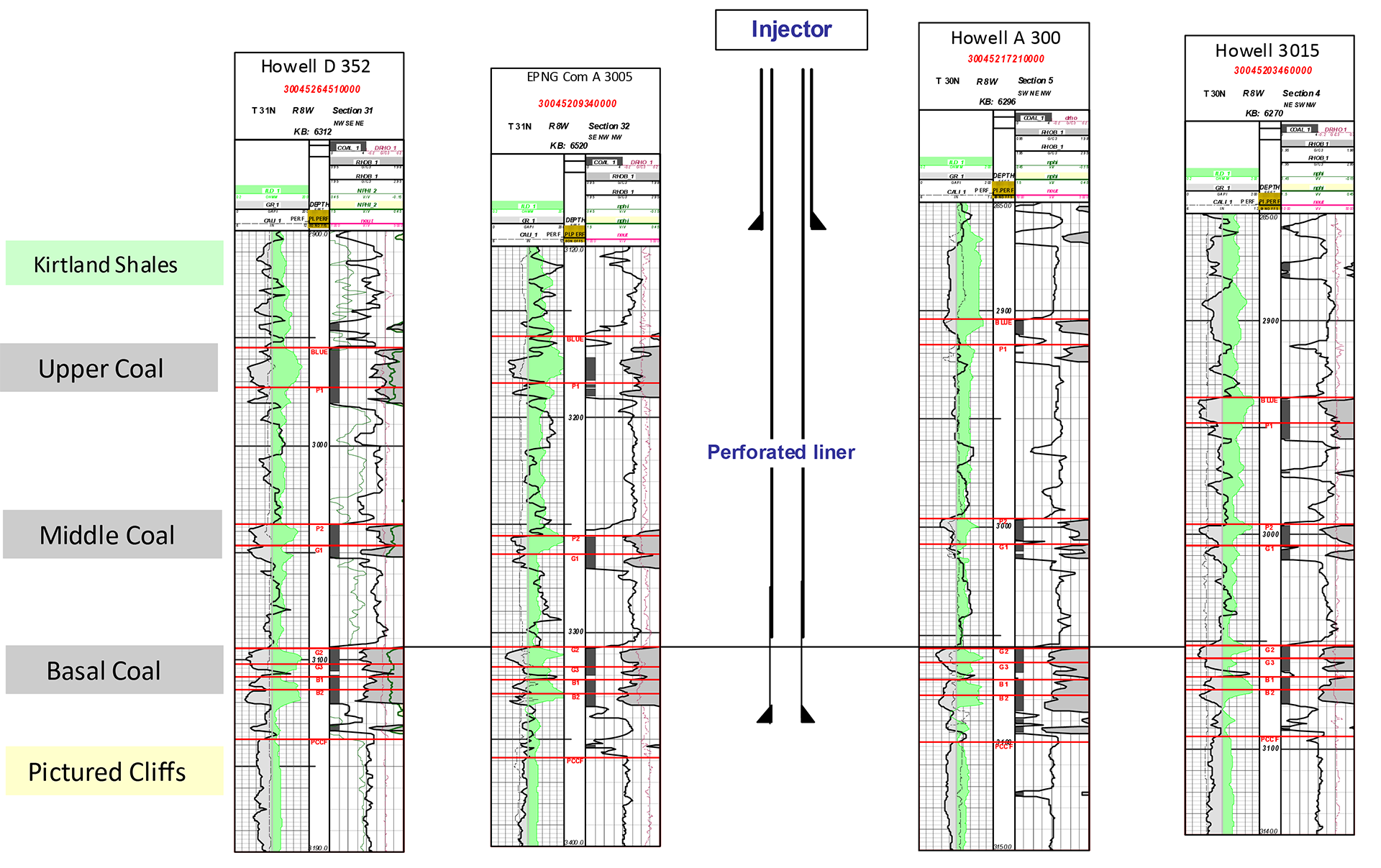

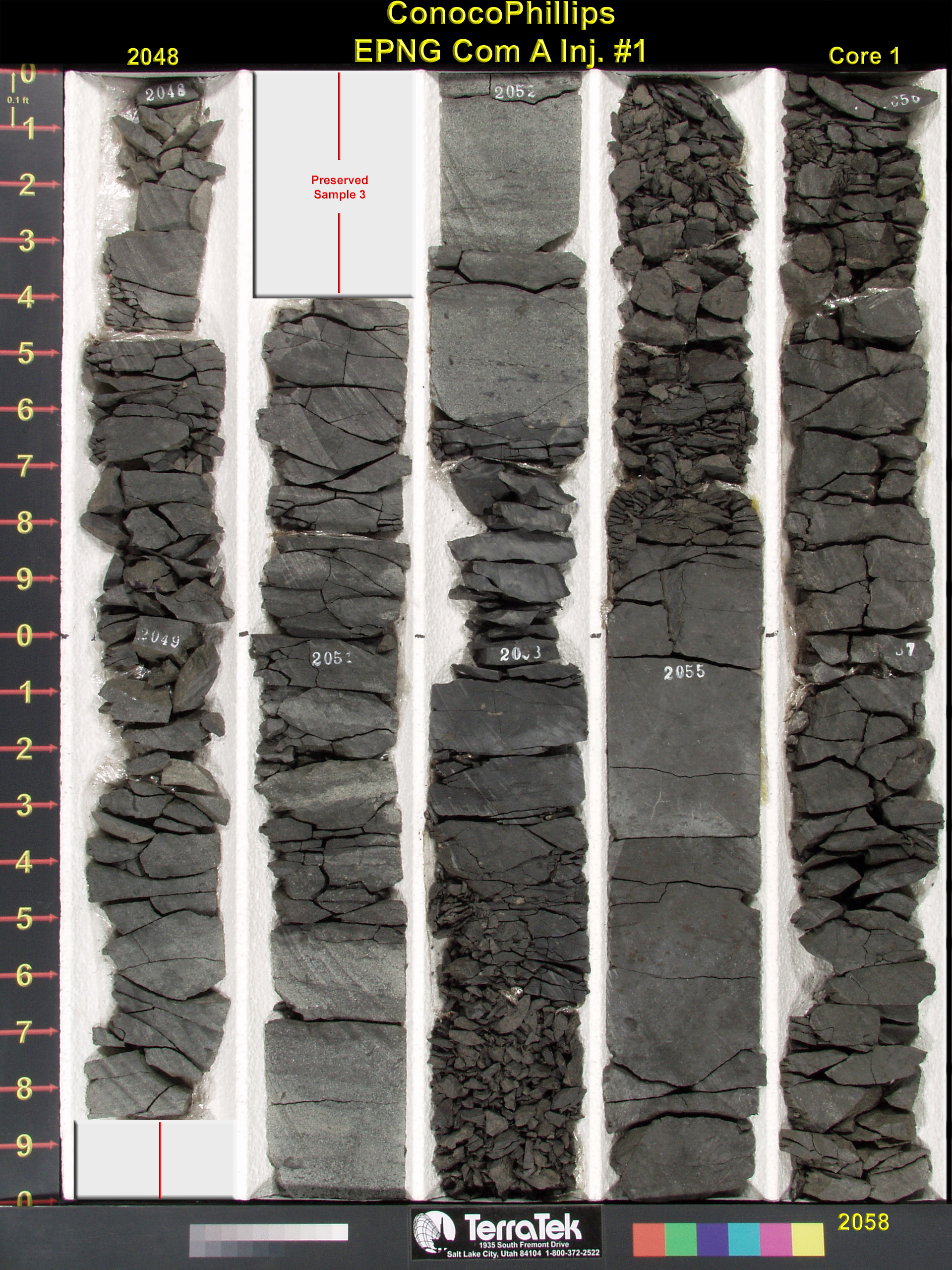

The Pump Canyon study area included 31 coalbed methane production wells located in a nine-section area. 3D seismic data, along with core and log analysis, were used to characterize the reservoir. The primary gas-producing horizons in this area are coalbeds in the Upper Cretaceous Fruitland Formation. The Fruitland is a mixture of mudstones, siltstones, sandstones, carbonaceous shales, and coals deposited in a nearshore swamp environment on the margins of the Western Interior Seaway.

The coals at Pump Canyon occur at depths of approximately 914 meters (3,000 feet) and are approximately 23 meters (75 feet) thick, split among three seams over an approximate 53-meter (175-foot) gross interval. 3D seismic analysis reveals considerable stratigraphy. The lower Fruitland coal reflection events are fairly continuous across the site, whereas the middle and upper Fruitland coal events are fairly discontinuous and difficult to correlate through the surrounding area. The detailed seismic view also reveals considerable local structural complexity not generally observed in well log-derived cross sections. Thinning of the Fruitland sequence observed along a NW-SE trend may be associated with differential compaction over northwest trending shoreline sand bodies in the upper Pictured Cliffs Sandstone. A variety of open and healed fracture trends are penetrated between subsurface depths of approximately 113 meters (370 feet) to approximately 892 meters (2,925) feet within the upper Fruitland formation. The distributions are marginally nonrandom, at best.

A detailed study by Ayers and Zellers (1994) conducted near the pilot site also revealed considerable complexity in the Fruitland depositional systems. Work by Wray (2000) and Fassett (1997) speculated that continuity of subsurface coals over distances of a mile (1.6 kilometers) is speculative, at best. Pinchouts, local fault truncations, channel scour, and facies changes are all encountered in the Fruitland coals.