Carbon Storage Atlas

Phase I Overview

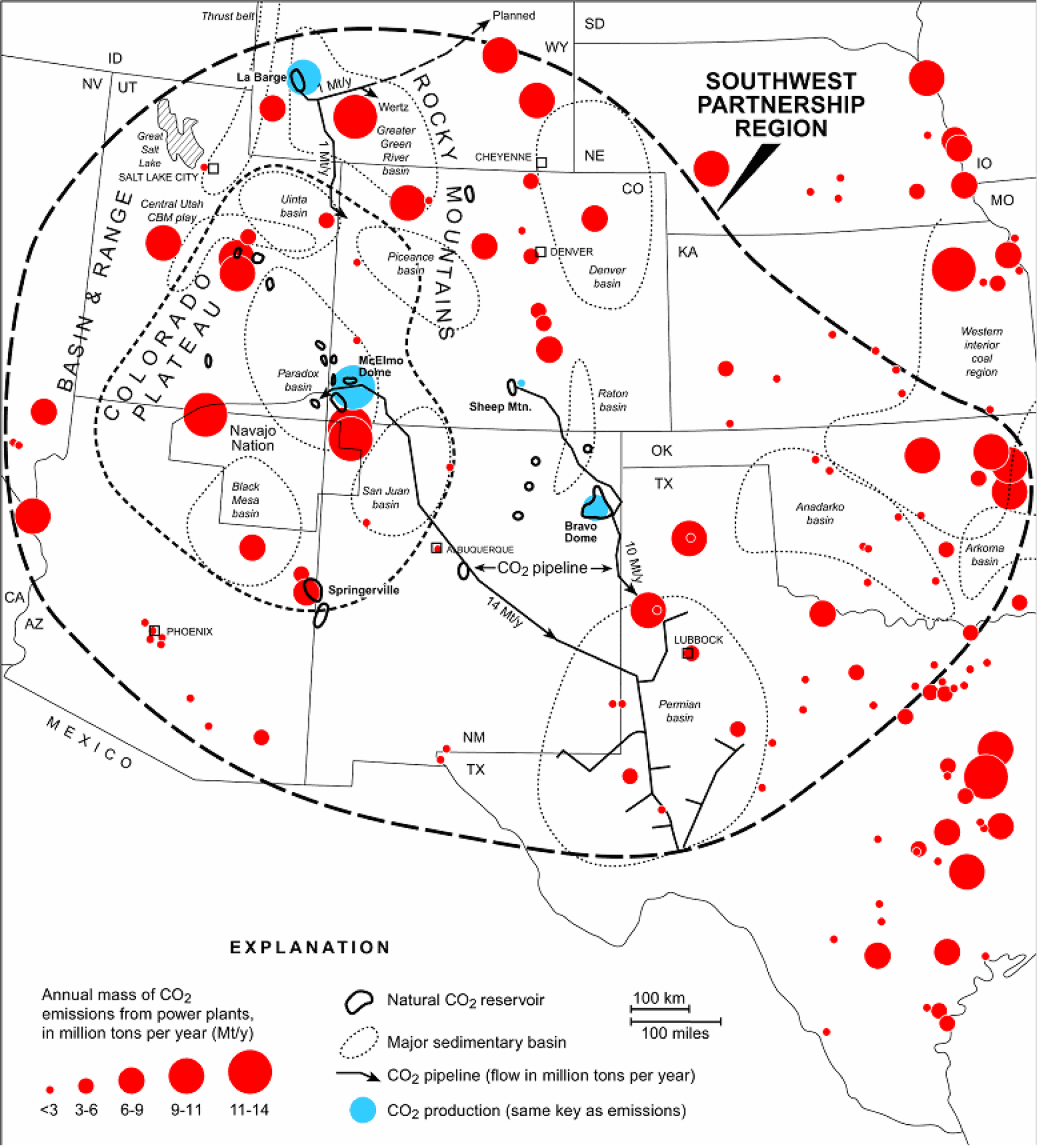

The region of the Southwest Regional Partnership on Carbon Sequestration (SWP) covered large portions of the southwest United States, as well as smaller areas in adjacent states. The region is energy-rich, and is home to some of the largest oil, gas, and coal deposits in the United States. It is unique in that it contains two major carbon dioxide (CO2) pipeline networks that transport more than approximately 27.2 million metric tons/year of natural subsurface CO2 from southern Colorado and northern New Mexico to petroleum fields in other parts of the region, in particular the Permian basin, for enhanced oil recovery.

The region is home to several large point source CO2 emitters. The 10 largest coal-fired power plants in the region produced more than approximately 127 million metric tons of CO2/year (roughly half the region’s total CO2 emissions). A main objective of SWP’s Phase I project was to forecast options to achieve an 18% reduction in carbon intensity by 2012. For example, at that time, one of the partnership’s specific goals was to reduce the region’s greenhouse gas (GHG) intensity to less than 182 metric tons carbon equivalent/gross state product ($million). Most of the SWP Phase I project tasks were designed to optimize preparation and action plans for reducing the region’s GHG intensity.

Story of Interest

The Southwest Regional Partnership on Carbon Sequestration (SWP) investigated a comprehensive set of options for carbon dioxide (CO2) reduction. Brine mineralization was evaluated by the team as an option to store CO2. One “vision” of this effort examined the possibility of combining produced oilfield brines with CO2 from a power plant, and forming limestone bricks for construction purposes.

Another unusual idea was inspired by the example of teeth. All of us grow them, in part by combining cations in our body with CO2; however, without a catalyst such as carbonic anhydrase (HCA II) to hasten the necessary chemical reactions, a tooth would require centuries to form. Results illustrated that mineralization can occur under appropriate conditions and that the rate of necessary reactions can be enhanced by the use of enzymes that catalyze the hydration of CO2, a rate-limiting step for this process. Research using the enzyme HCA II with synthesized brines suggested that the hydration step can indeed be accelerated and that calcium carbonate can be precipitated from both low- and high-cation concentration solutions. This SWP-supported research also demonstrated an approach for flow-through applications, as well as robustness with respect to potential industrial constituents such as sulfur oxides (SOX), nitrogen oxides (NOX), arsenic (As), and mercury (Hg).

Ultimately, the economics of storage via brine mineralization was forecasted to be prohibitively expensive. Nevertheless, the SWP Phase I team conducted preliminary assessments of brine resources in the southwest, focusing on brine chemistries and volumes, as well as the relationship of brine mineralization to associated processes such as oil production.

Lessons Learned

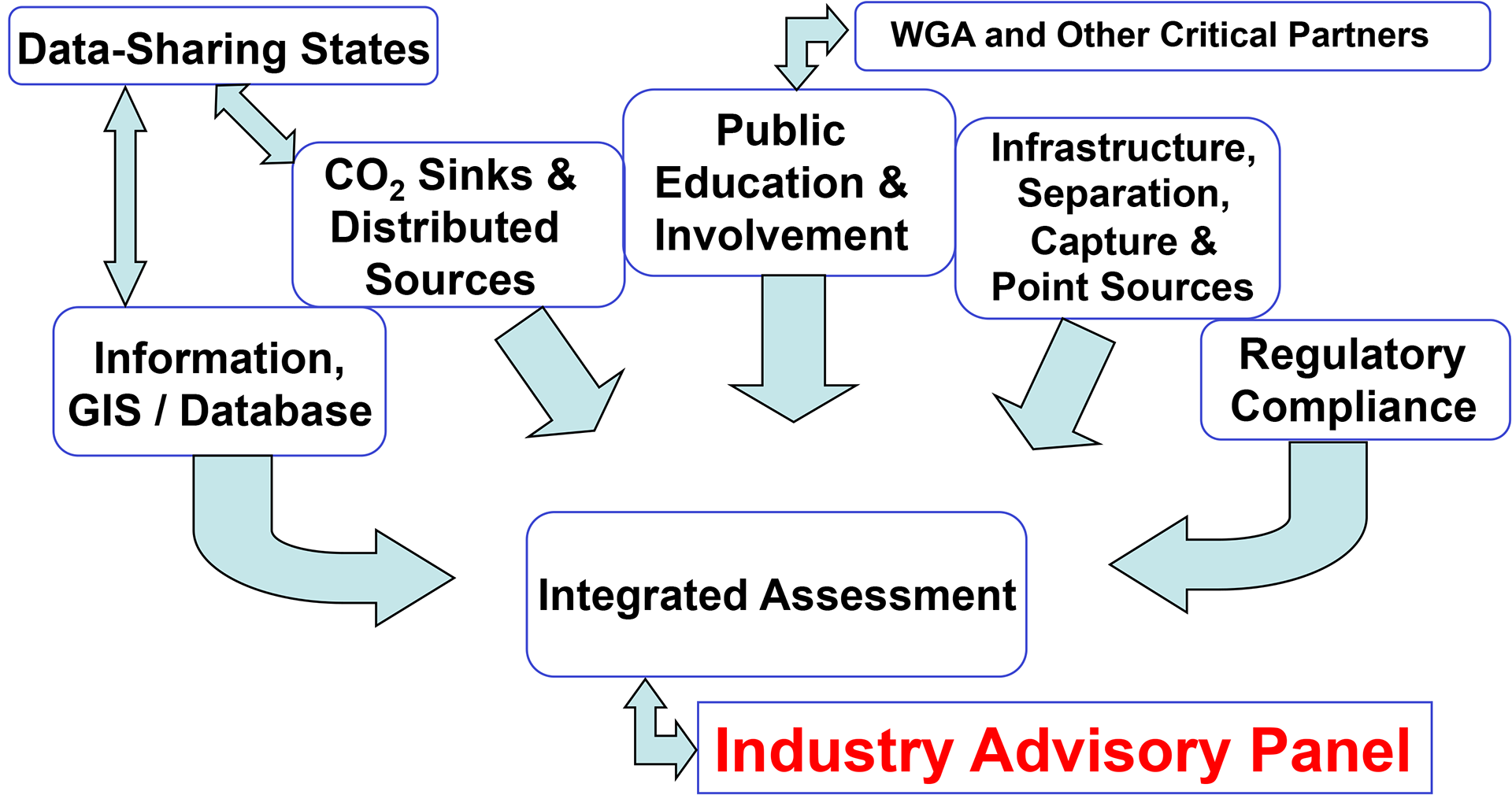

Ultimate goals of the Southwest Regional Partnership on Carbon Sequestration (SWP) Phase I Program were to identify carbon sources and sinks in the southwestern United States, link storage options with sources, rank or prioritize the options, and develop an action plan for implementing those options.

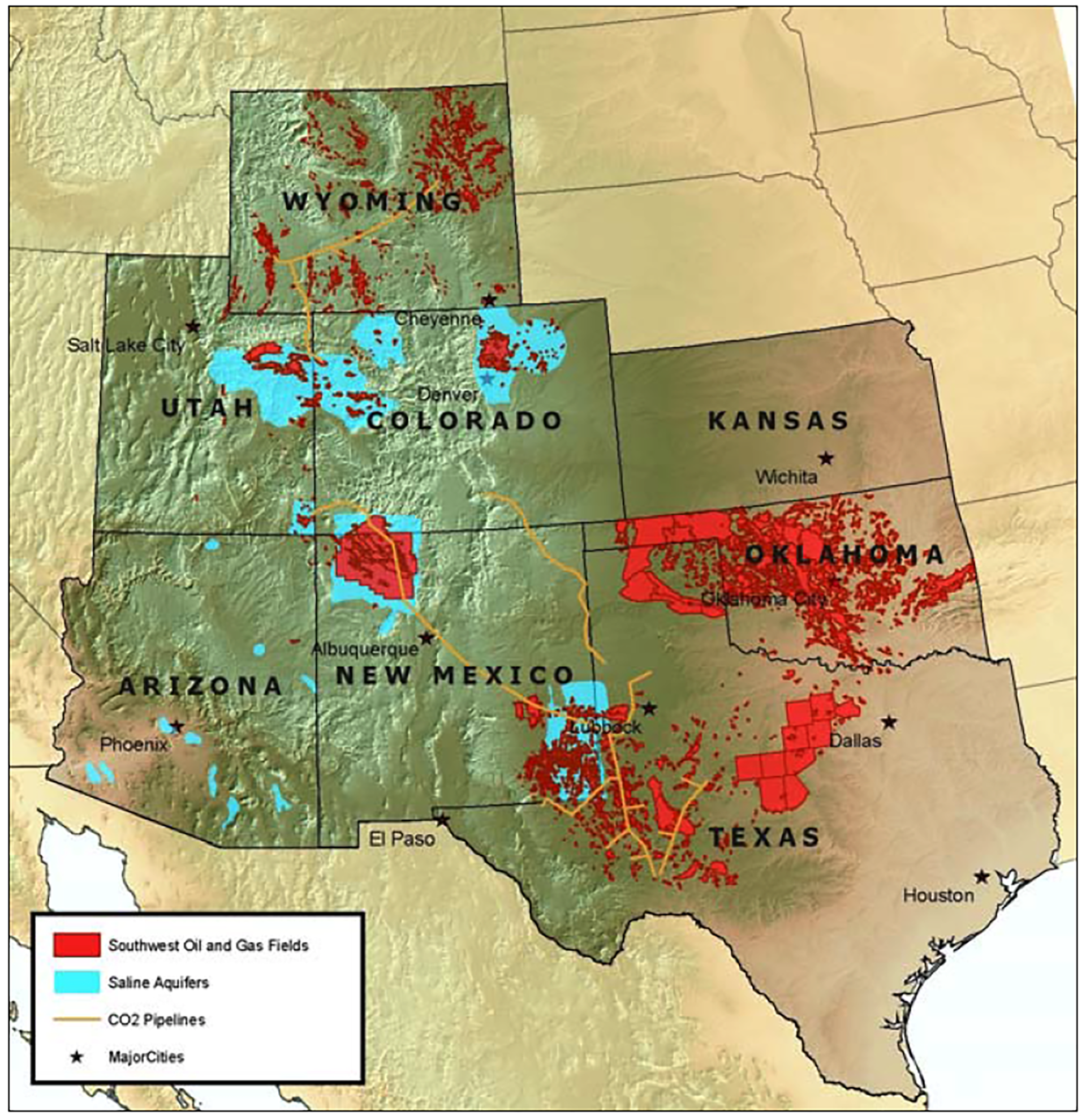

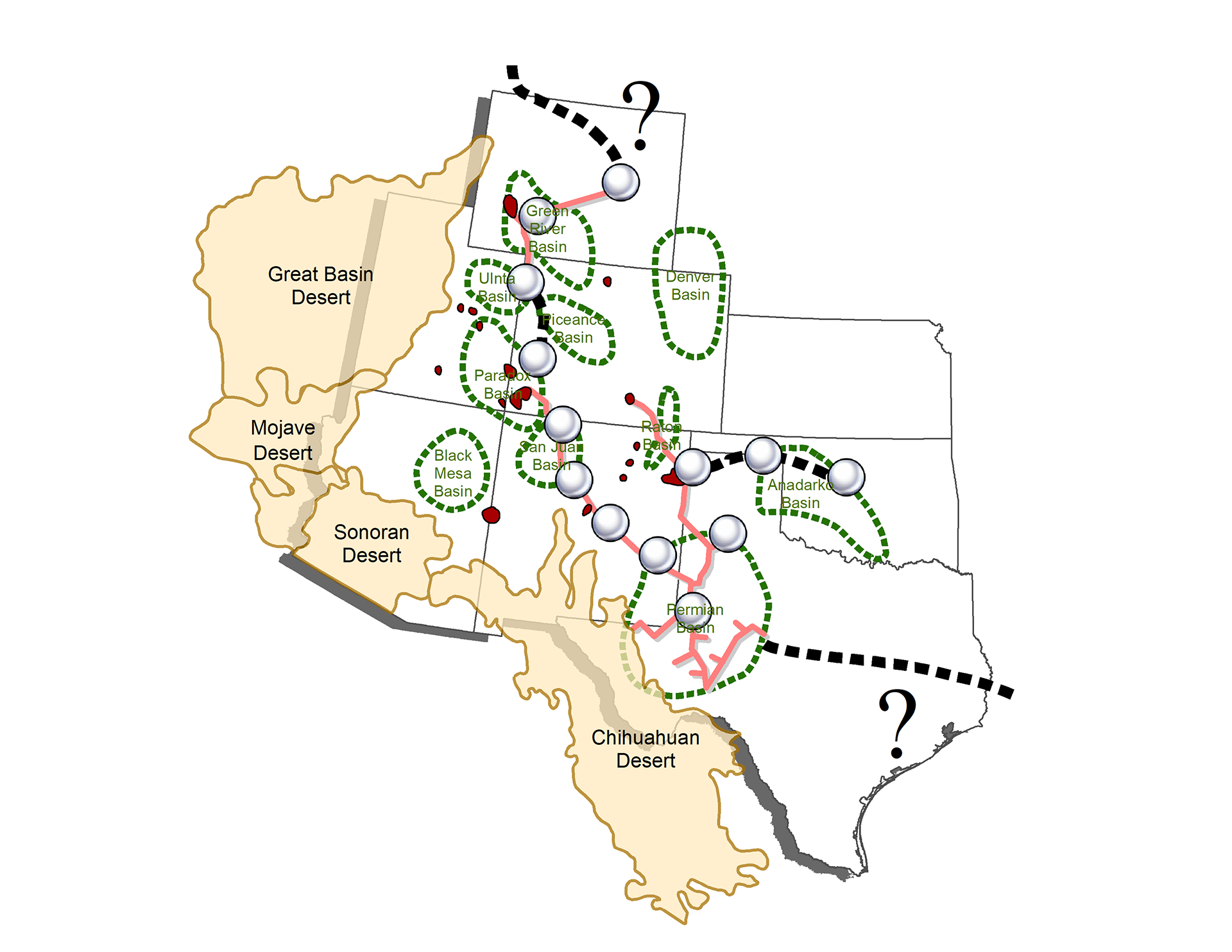

SWP assembled a comprehensive database of readily available data regarding carbon dioxide (CO2) sinks and sources in the region (Figures 2 and 3). The team also instigated a protocol for gathering of relevant data not readily available (e.g., from non-digital or private non- published data sources) and developed and deployed a website network to facilitate storage of data and information sharing in the region. SWP assembled details of existing regulatory and permitting requirements and developed action plans for assessing potential risks and for monitoring, verification, and accounting (MVA) of storage approaches for the region (Figure 4). In addition to their website, designed for public outreach and education, SWP held several public conferences and “town hall” meetings to educate the public about possible storage approaches.

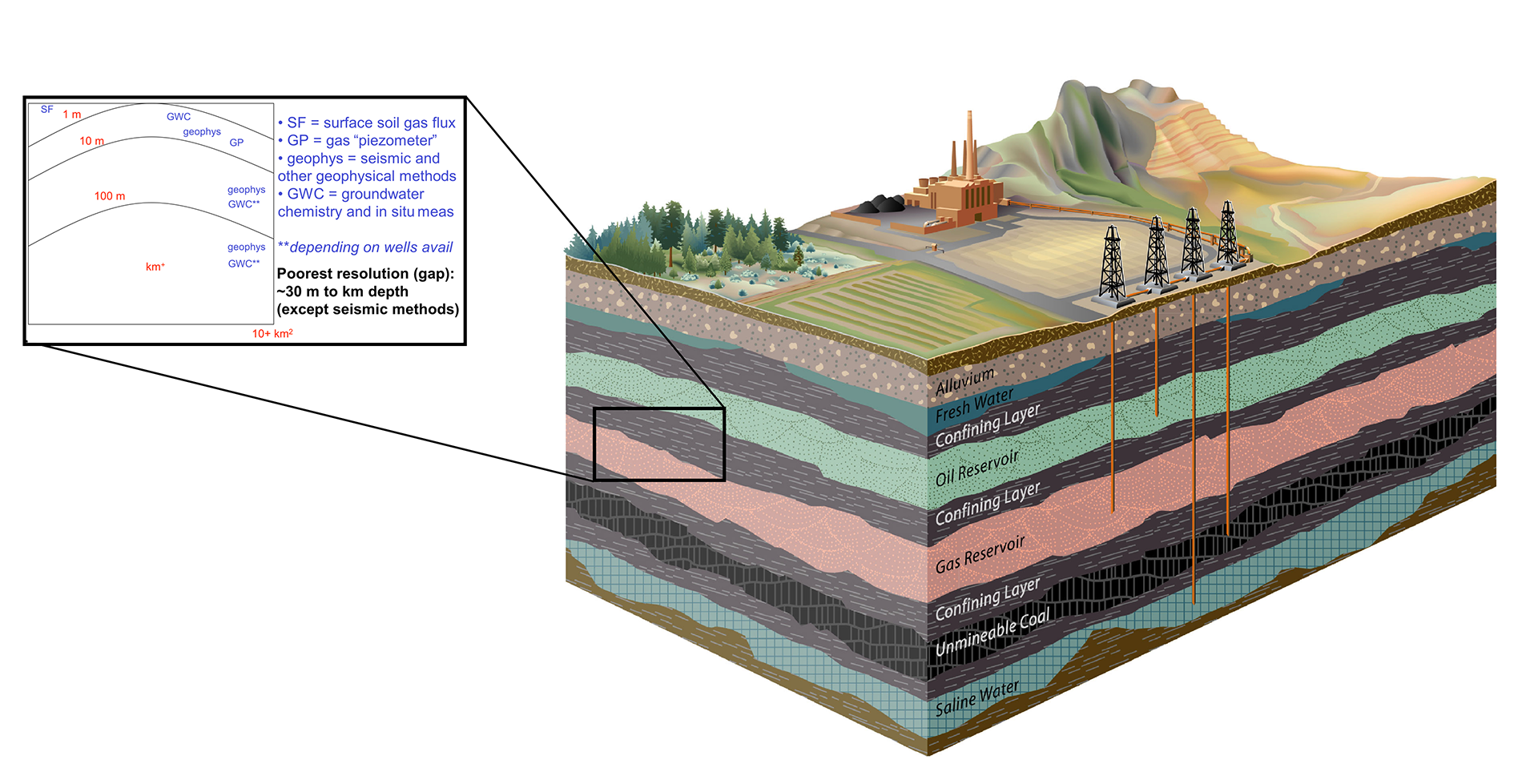

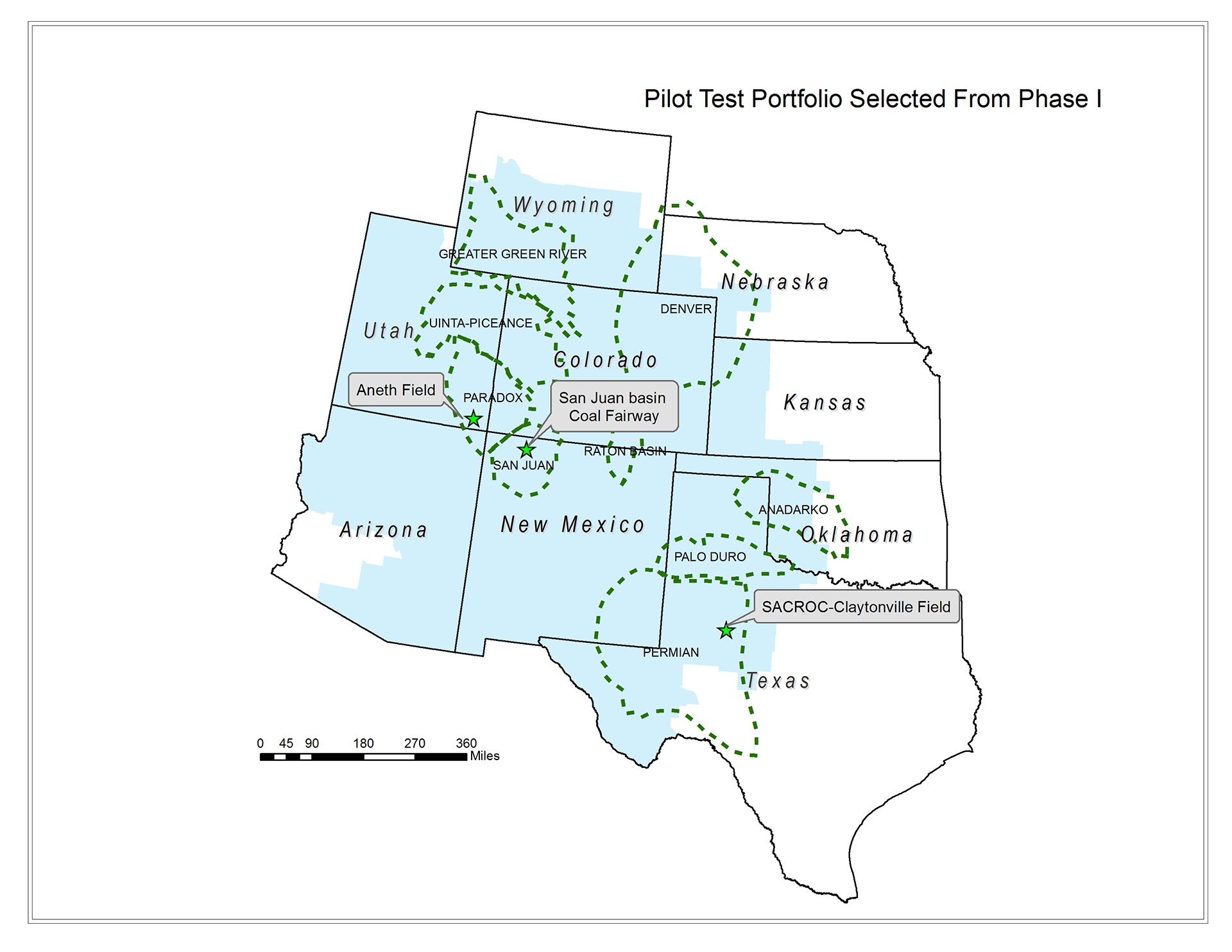

All partners took an active role in evaluating and ranking optimum sites and storage technologies for capture and storage of CO2 in the southwest region (Figures 5 and 6). SWP identified gaps in many aspects of potential storage deployment strategies, from possible problems with technology and engineering, to gaps in regulatory frameworks and limitations in existing MVA methodologies needed to validate long-term storage efforts. Action plans for five possible Phase II carbon storage pilot tests in the region were developed, including evaluating technical and non-technical aspects necessary for developing and carrying out those pilot tests (Figure 7).

Lessons learned include:

-

Linking sources to sinks with existing CO2 pipelines in the “String of Pearls approach” is ideal for the southwest region.

-

In the SWP region, the most convenient and practical “first opportunities” for storage would be to supplant the natural CO2 in these pipelines with power plant-sourced CO2. With such an approach, the region would meet, at the least, minimum greenhouse gas (GHG) intensity reduction targets for the region.

-

MVA is among the most critical aspects of storage implementation. MVA deployment and associated modeling are primary vehicles for determining how well a project meets or exceeds performance targets of the Carbon Storage Roadmap, and was central to SWP risk assessment and risk mitigation approaches. Extensive MVA protocols, including direct and indirect approaches, were proposed, and specific MVA technologies proposed for each pilot-test site were selected based on the unique geologic setting of the site and to maximize SWP’s ability to test MVA technology efficacy.

Partners

- Lead:New Mexico Institute of Mining and Technology

- Arizona Geological Survey

- Colorado Geological Survey

- Dine College (Navajo Nation)

- Gas Technology Institute

- Los Alamos National Laboratories

- New Mexico Bureau of Geology and Mineral Resources

- New Mexico Petroleum Recovery Research Center

- New Mexico State University

- Oklahoma Geological Survey

- Sandia National Laboratories

- Texas Bureau of Economic Geology

- U.S. Department of Agriculture

- University of Oklahoma

- University of Utah

- Utah AGRC

- Utah Geological Survey