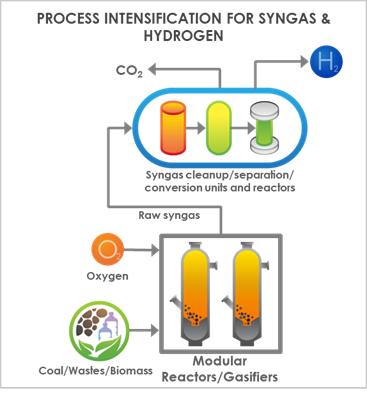

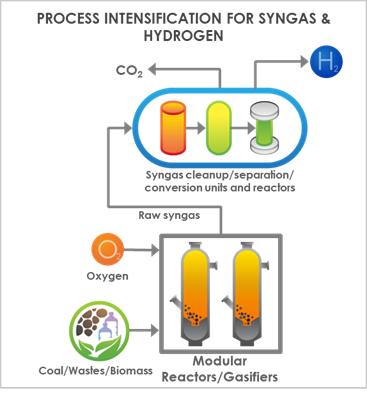

The Process Intensification for Syngas & Hydrogen key technology area addresses control of chemical reactions in modular and intrinsically efficient reactors, allowing for streamlined processes with well-coordinated unit operations, and with a focus on gasification of varied solid feedstocks into syngas, syngas cleanup, efficient hydrogen and carbon dioxide separation supporting carbon storage, and syngas conversion. Hydrogen and syngas serve as ideal feedstocks for liquid fuels or chemicals production. Improved reactors and processes for gasification, syngas separations and cleanup, and conversion of syngas into hydrogen or other valuable products will enable integrated systems with higher availability, reliability, efficiency and flexibility, resulting in lowered costs of production and excellent environmental performance of versatile solid feedstock-based energy systems.

The Process Intensification for Syngas & Hydrogen key technology area addresses control of chemical reactions in modular and intrinsically efficient reactors, allowing for streamlined processes with well-coordinated unit operations, and with a focus on gasification of varied solid feedstocks into syngas, syngas cleanup, efficient hydrogen and carbon dioxide separation supporting carbon storage, and syngas conversion. Hydrogen and syngas serve as ideal feedstocks for liquid fuels or chemicals production. Improved reactors and processes for gasification, syngas separations and cleanup, and conversion of syngas into hydrogen or other valuable products will enable integrated systems with higher availability, reliability, efficiency and flexibility, resulting in lowered costs of production and excellent environmental performance of versatile solid feedstock-based energy systems.

Philosophy

Current reactor design (including traditional large-scale coal and petroleum coke fueled gasifiers, and small-scale biomass gasifiers) is characterized by simplistic geometries, limited control over reactants inside, and incremental advancements with surprisingly little significant change over time. However, advances in technology have resulted in tools to allow development of more sophisticated reactor concepts that will allow more precision and control in these reacting systems, and which can be developed more quickly and inexpensively. Process intensification with well-integrated/coordinated unit operations and resulting synergies can help realize sustainable and cost-effective energy system processes.

Strategy

The Gasification Systems Program is pursuing development in promising areas of advanced gasification technologies to lower costs and increase efficiency of modular syngas production and syngas conversion to value-added products. The program is leveraging ongoing technological advances to make rapid improvements in reactor engineering and design. Notably, these include exponentially increasing computing power at lower costs, which is expected to allow increasingly realistic computer models to simulate feedstock conversion during gasification, and breakthroughs in advanced manufacturing to significantly drop the capital costs for small-scale reactors and modular plants.

In the biomass gasification field, moving bed or fixed bed gasifiers and fluidized bed gasifiers at low pressure are common, given their relative flexibility in handling varying feed streams and suitability to the sizes needed for typical applications. However, oxygen- or steam-blown highly pressurized gasification of biomass-containing feed streams has been advocated for R&D, which should enable higher efficiency and reaction intensity of these systems.

Accordingly, NETL supports R&D of high-pressure modular gasifiers, high-pressure feeding of lower quality fuels including biomass/waste blends, lower cost air separation for modular systems, and better integration with carbon capture and storage. The R&D strategy is to continue pursuing gasifier technology for higher efficiency utilization of waste/biomass blends and reduction of cost of these gasification systems.

Biomass/wastes cogasification

Several projects in the program are focusing on the cogasification of coal/waste plastic/biomass feedstocks to produce syngas and hydrogen with greatly reduced CO2 emissions:

Producing Clean Hydrogen Using a Modular Two-Stage Intensified Membrane-Enhanced Catalytic Gasifier — West Virginia University Research Corporation is developing a process-intensified two-stage bubbling fluidized bed gasifier for hydrogen production from biomass. The configuration integrates a membrane separator and precombustion carbon dioxide capture system with syngas recycle, intensifying the gasification system to increase efficiency and use significantly less equipment than traditional systems.

Catalytic Membrane Reactors Based on Carbon Molecular Sieve Hollow Fiber Membranes for Sustainable and Modular Hydrogen Production — The State University of New York (SUNY) is developing a process-intensified gasification system for modular hydrogen production from waste biomass using catalytic membrane reactors based on carbon molecular sieve hollow fiber membranes that selectively remove hydrogen during the high-temperature water-gas shift reaction.

Machine Learning Enhanced LIBS to Measure and Process Biofuels and Waste Coal for Gasifier Improved Operation — Energy Research Company and Lehigh University are developing technology to measure biomass and waste coal gasifier feedstocks in-situ and in near real time, resulting in immediate and time sensitive fuel data that gasifier operators can use in a feedback or feedforward control scheme to maximize performance and avoid negative effects of ash in feedstocks.

Hydrogen Cost Reductions via Process Intensification & Modularization

The following projects concern production of low-cost hydrogen from sustainable feedstocks that include biomass, with emphasis on process intensification, modular process units, and increased system efficiency:

Process Intensification of Hydrogen Production through Sorption-Enhanced Gasification of Biomass — This joint University of Utah and Idaho National Laboratory project is investigating the feasibility of sorption-enhanced waste biomass gasification for production of hydrogen-rich syngas in a dual fluidized bed reactor, evaluating additions of limestone sorbent plus fluidizing the reactor with an oxygen/carbon dioxide mix to improve hydrogen yield and production cost effectiveness.

Intensification of Hydrogen Production Enabled by Electrochemical Pumping Module for Purification and Compression — This Washington University project is developing innovative electrochemical hydrogen pump technology to reduce the cost of hydrogen production from small-scale (5–50 MW) biomass gasification units. Process intensification by combining hydrogen purification and compression into a single step, by virtue of a single modular electrochemical purifier/pump, should allow significant energy penalty reductions and cost savings over conventional separate hydrogen separation and compression steps.

Modular Biomass Gasification for Co-Production of Hydrogen and Power — The University of North Dakota and Envergex LLC plan to develop a novel process-intensified and modular combined hydrogen, heat and power system concept in the size of 5–10 megawatt-electric equivalent. The process would combine the use of a novel, iron-based oxygen-carrier material with multifunctionality for syngas purification, hydrogen production, and carbon dioxide separation, with a commercially available modular bed gasification system patented by Singularity Energy Technologies and known as the Sandwich™ Gasifier, specifically designed for variable quality feedstocks.

Producing Clean Hydrogen Using a Modular Two-Stage Intensified Membrane-Enhanced Catalytic Gasifier — West Virginia University Research Corporation is developing a process-intensified two-stage bubbling fluidized bed gasifier system integrated with a carbon molecular sieve membrane separator and precombustion carbon dioxide capture system with syngas recycle, which should enable highly efficient modular hydrogen production from biomass. The bubbling fluidized bed gasifier will utilize a multifunctional catalyst to enhance the reaction rates of biomass reforming, tar cracking, and water gas shift functions.

An Intensified Process to Transforming the Production of Carbon-Neutral Hydrogen — Clarkson University and University of Wisconsin Madison are developing a hydrogen-selective membrane-assisted water-gas shift (WGS) reactor concept in this project. In this approach, hydrogen produced by the WGS reaction would be simultaneously separated and removed from the mixture gas without undergoing other treatments that remove pollutants, which would have the benefit of eliminating a separate syngas purification step. The requirement for a hydrogen-selective membrane material with long-term stability and high permeability and selectivity may be met by ternary alloys of Pd-Ag-Au membranes on support. The project involves testing/down-selecting membranes to establish hydrogen production feasibility, along with life cycle assessment and technoeconomic analysis to determine cost effectiveness.

Catalytic Membrane Reactors Based on Carbon Molecular Sieve Hollow Fiber Membranes for Sustainable and Modular Hydrogen Production — The State University of New York (SUNY) is developing catalytic membrane reactors based on carbon molecular sieve (CMS) hollow fiber membranes. The reactors would be designed to selectively remove hydrogen during the high-temperature water-gas shift (WGS) reaction, simplifying the WGS reactor configuration and integrating hydrogen separation with the WGS reactor instead of requiring a separate downstream hydrogen separation step. Key challenges include attaining thermally stable, processible polymer-derived CMS membranes, and designing/preparing new multicomponent carbon dioxide-tolerant nano-catalysts for the WGS reaction.

Enabling Low Carbon Feedstocks for Gasification — Oak Ridge National Laboratory is helping to enable hydrogen cost reductions through characterizing municipal solid waste and low-carbon feedstocks behavior in early stages of catalytic gasification. Their approach leverages their sophisticated abilities in advanced material science techniques including study of transforming solids undergoing gasification, as viewed by in-situ neutron scattering and imaging techniques.

Machine Learning Enhanced LIBS to Measure and Process Biofuels and Waste Coal for Gasifier Improved Operation — Energy Research Company is collaborating with Lehigh University to develop an instrument to measure the feedstock to a gasifier in-situ and in near real time, resulting in immediate and time sensitive fuel data that gasifier operators can use in a feedback or feedforward control scheme to maximize performance and avoid negative effects of ash in feedstocks. The instrument combines laser induced breakdown spectroscopy (LIBS) with artificial intelligence. Current objectives are to extend prior measurement success by better simulating a commercially operating gasifier and determining the exact gasifier performance from measurements using the machine learning-LIBS data as an input to GTI’s gasifier simulator.

On-site NETL Research

NETL’s Research and Innovation Center is developing innovative gasification technologies that enable process intensification and/or reduce the overall cost of small-scale energy conversion through improved methods, materials and approaches. Currently, the technological areas are under investigation:

- Advanced Gasifier Design — this work emphasizes the application of NETL’s multiphase flow computational fluid dynamics tools and reactor expertise to study and develop novel gasification-based designs (such as of systems for hydrogen production with reduced carbon emissions). Simulations are being performed to guide design and scale-up of gasification reactors for mixed feedstocks, including biomass, plastics and municipal solid waste. Simulations will verify that the pilot-scale system will meet the required design parameters and help guide reactor optimization.

- Refractory Materials for Multifuel Gasification — this work is addressing the problem of identifying suitable combinations of refractory ceramics and refractory support structures to withstand the unusual contaminants in mixed coal/biomass/plastic-fueled gasifier environments.

- Microwave Reactions for Gasification — NETL is investigating use of microwave-driven reactions for gasification, enabling conversion of blended feed streams of biomass, waste plastic, coal fines and/or municipal solid waste to hydrogen, value-added chemicals, and carbon materials at low temperatures with high selectivity, efficiency and low cost.

Other key technologies within Gasification Systems include the following:

The Process Intensification for Syngas & Hydrogen key technology area addresses control of chemical reactions in modular and intrinsically efficient reactors, allowing for streamlined processes with well-coordinated unit operations, and with a focus on gasification of varied solid feedstocks into syngas, syngas cleanup, efficient hydrogen and carbon dioxide separation supporting carbon storage, and syngas conversion. Hydrogen and syngas serve as ideal feedstocks for liquid fuels or chemicals production. Improved reactors and processes for gasification, syngas separations and cleanup, and conversion of syngas into hydrogen or other valuable products will enable integrated systems with higher availability, reliability, efficiency and flexibility, resulting in lowered costs of production and excellent environmental performance of versatile solid feedstock-based energy systems.

The Process Intensification for Syngas & Hydrogen key technology area addresses control of chemical reactions in modular and intrinsically efficient reactors, allowing for streamlined processes with well-coordinated unit operations, and with a focus on gasification of varied solid feedstocks into syngas, syngas cleanup, efficient hydrogen and carbon dioxide separation supporting carbon storage, and syngas conversion. Hydrogen and syngas serve as ideal feedstocks for liquid fuels or chemicals production. Improved reactors and processes for gasification, syngas separations and cleanup, and conversion of syngas into hydrogen or other valuable products will enable integrated systems with higher availability, reliability, efficiency and flexibility, resulting in lowered costs of production and excellent environmental performance of versatile solid feedstock-based energy systems.