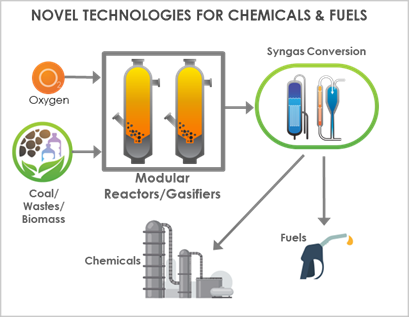

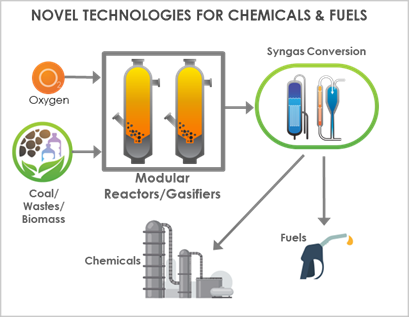

Novel Technologies for Chemicals & Fuels focuses on improved designs and strategies for efficient and low-cost gasification-based systems enabling innovative process routes to high-value energy products from solid fuel resources. Syngas from gasification of solid fuel resources such as coal and petroleum coke has versatile end uses. Plants have demonstrated successes in producing liquid transportation fuels, methanol, acetyl chemicals and hydrogen, which is commonly used in turn as a feedstock for ammonia synthesis (and fertilizer) and for upgrading oil refinery products.

Novel Technologies for Chemicals & Fuels focuses on improved designs and strategies for efficient and low-cost gasification-based systems enabling innovative process routes to high-value energy products from solid fuel resources. Syngas from gasification of solid fuel resources such as coal and petroleum coke has versatile end uses. Plants have demonstrated successes in producing liquid transportation fuels, methanol, acetyl chemicals and hydrogen, which is commonly used in turn as a feedstock for ammonia synthesis (and fertilizer) and for upgrading oil refinery products.

Philosophy

In the late 20th century, several highly successful coal gasification plants were built and operated in the United States. These included Eastman Chemical’s Kingsport Tennessee Plant, which produces acetyl chemicals, the Great Plains Synfuels Plant, which currently produces hydrogen used for ammonia and fertilizer synthesis, and groundbreaking integrated gasification combine cycle power plants including Wabash River IGCC and Polk Power IGCC. The IGCC plants (including these domestic examples as well as IGCC power plants in Europe) were noted for excellent efficiency and environmental performance, but eventually they were all decommissioned due to market pressures and increasingly inexpensive electricity generation alternatives including natural gas-fueled power plants. Interestingly, the nonpower coal gasification plants remained economically competitive and remain in operation today, efficiently producing valuable chemicals and products from inexpensive domestic coal. Internationally, the same trend can be observed, with coal gasification-based chemicals synthesis capacity currently being added in China and continued interest in gasification in India and southeast Asia.

This experience suggests that solid fuel-based gasification for the right end products has continued viability and deserves ongoing attention in R&D to further improve efficiency, cost effectiveness and performance.

Strategy

The NETL Gasification Systems program accords with this philosophy with its recent efforts in modular gasification-based systems for production of hydrogen that can be utilized in fuel synthesis, chemicals/ammonia and fertilizer production, and more. R&D of these systems should continue toward demonstration of technical feasibility at commercial scale and reduction of investment risk, which have been identified by the R&D community as key research and policy needs for market-competitive gasification systems development.

NETL supports R&D of efficient high-pressure modular gasifiers utilizing of a wide range of solid fuels beyond coal including biomass/waste blends, with the strategy of attaining a synergy of high-value products synthesis while simultaneously providing a means to gainfully dispose of unrecyclable wastes and excess biomass. The R&D strategy is to continue pursuing gasifier technology for higher-efficiency gasification of varied solid feedstocks, conversion to high-value end products, and reduction of those technology costs along the entire energy system chain.

Projects

Hydrogen from High-Volume Waste Materials and Biomass

The following projects concern technology development supporting production of hydrogen from blended feedstocks that include biomass, waste coal, waste plastics and municipal solid wastes (MSW), with carbon capture included in process systems:

Advancing Entrained-Flow Gasification of Waste Materials and Biomass for Hydrogen Production — This University of Utah project is studying gasification of blends of biomass and high-volume waste materials (in the form of various slurried mixtures of coal, biomass liquid and waste plastic oil) to produce hydrogen and improve feedstock preparation and feeding to enhance gasifier performance and conversion. A 1-ton/day pressurized, oxygen-blown entrained-flow gasifier outfitted with a new flexible fuel gasifier burner based on proven hot oxygen burner technology is being utilized, which should help improve feeding flexibility, feed quality and cost performance.

Fluidized Bed Gasification for Conversion of Biomass and Waste Materials to Renewable Hydrogen — A Gas Technology Institute (GTI)-led team is evaluating the chemical kinetics and gasification behavior of biomass and waste material feedstock blends, as well as a safe and reliable feeding mechanism for those blends into GTI's U-GAS® pilot-scale gasifier. This is to establish the basis for development of a 5–50 megawatt-scale hydrogen production plant using the U-GAS technology fed with the unusual combination of biomass, waste plastic and municipal solid waste.

Hydrogen Production from High Volume Organic Construction and Demolition Wastes — The Energy and Environmental Research Center at the University of North Dakota will study gasification of construction and demolition debris-containing treated lumber to produce clean hydrogen, while addressing the challenge of simultaneously capturing/storing arsenic contained in this contaminated feedstock. Integrated system design for an oxygen-blown fluid-bed gasification system, including gasifier structure and operating conditions, unit materials, tar cracking and gas filtration is in scope.

Performance Testing to Advance Modular, Moving-Bed Gasification for the Generation of Low-Cost, Clean Hydrogen from Biomass Mixed with Legacy Coal Waste, Waste Plastic, and/or Other Waste — Electric Power Research Institute Inc. (EPRI) is qualifying blended feedstocks of biomass mixed with legacy coal wastes, plastic wastes and refuse-derived fuel as feedstocks for moving-bed gasification for modular production of high-hydrogen content raw syngas that can be shifted to produce concentrated hydrogen. In particular, the effects of the various fuels on syngas compositions, organic condensate production, ash characteristics, and impacts on gasifier operations are the focus of the project.

Hydrogen Production from Modular CO2 Assisted Oxy-Blown Gasification of Waste Blends — Auburn University is developing a novel process to produce hydrogen from blended feedstock wastes via CO2-assisted oxy-blown gasification. The process involves integration of CO2-assisted oxy-blown gasification with novel, modular technologies for syngas cleanup and conditioning, including RTI’s fixed-bed warm desulfurization process, trace contaminant removal process, and advanced fixed-bed water-gas shift.

On-site NETL Research

NETL’s Research and Innovation Center's work includes analysis of gasification of alternative feedstocks and feedstock control for hydrogen production with sustainable CO2 emissions:

- Gasification of Waste Plastic To Enable a Circular Economy — NETL is exploring the gasification of alternative carbonaceous feedstocks, such as waste plastic, waste coal, and biomass to generate hydrogen with minimal CO2 emissions.

- Feedstock Control for Gasification — NETL is developing intelligent systems capable of controlling the blend of mixed plastic waste, biomass, MSW, and waste coal supplied to a modular gasification system for production of hydrogen with carbon capture and storage. Actively controlling the blend of waste plastics and other materials fed to a gasifier will make its operation more stable and enable the optimization of its operation based on the feed stream composition.

DOE’s Hydrogen Program Plan

Other key technologies within Gasification Systems include the following:

Novel Technologies for Chemicals & Fuels focuses on improved designs and strategies for efficient and low-cost gasification-based systems enabling innovative process routes to high-value energy products from solid fuel resources. Syngas from gasification of solid fuel resources such as coal and petroleum coke has versatile end uses. Plants have demonstrated successes in producing liquid transportation fuels, methanol, acetyl chemicals and hydrogen, which is commonly used in turn as a feedstock for ammonia synthesis (and fertilizer) and for upgrading oil refinery products.

Novel Technologies for Chemicals & Fuels focuses on improved designs and strategies for efficient and low-cost gasification-based systems enabling innovative process routes to high-value energy products from solid fuel resources. Syngas from gasification of solid fuel resources such as coal and petroleum coke has versatile end uses. Plants have demonstrated successes in producing liquid transportation fuels, methanol, acetyl chemicals and hydrogen, which is commonly used in turn as a feedstock for ammonia synthesis (and fertilizer) and for upgrading oil refinery products.