Carbon Storage Atlas

Lat/Long

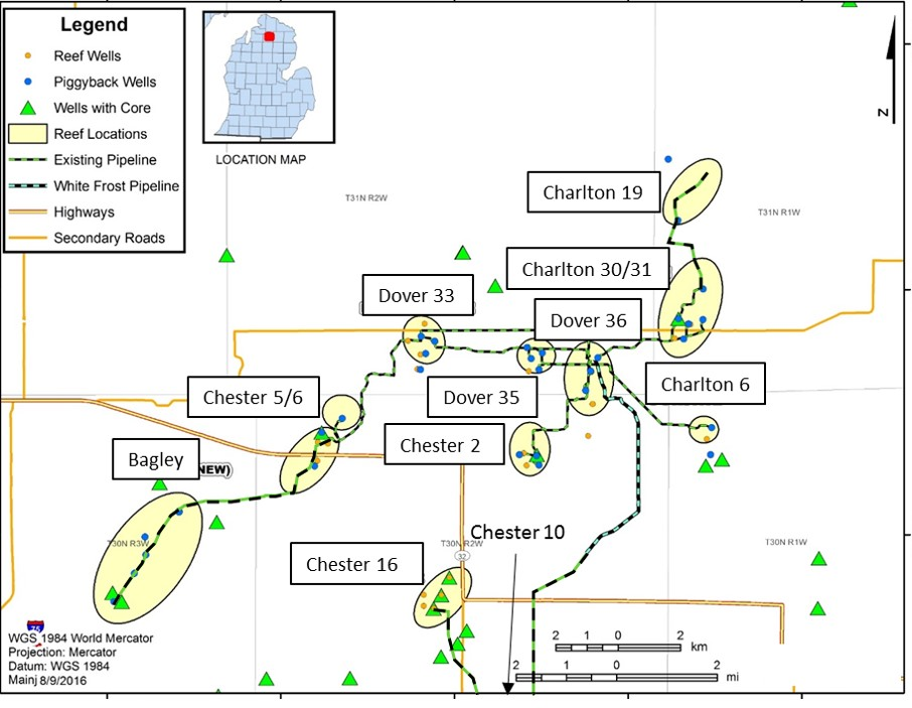

The Midwest Regional Carbon Sequestration Partnership (MRCSP) large-scale tests were conducted in Otsego County in northern Michigan Lower Peninsula. The field work was completed in carbon dioxide (CO2)-enhanced oil recovery (EOR) oil fields that inject CO2 and produce oil from a buried coral reef complex called the Niagaran Reefs. This area has a history of oil and gas production that provided infrastructure for the Phase III project, which included a CO2 pipeline, natural gas processing facility, CO2 compression equipment, oil processing facility, and injection wells. The geologic reef structures were approximately 1,524 to 2,134 meters (5,000 to 7,000 feet) deep in the subsurface. Locally, the area consisted of light forest, agriculture, and rural land use.

Regional Accomplishments

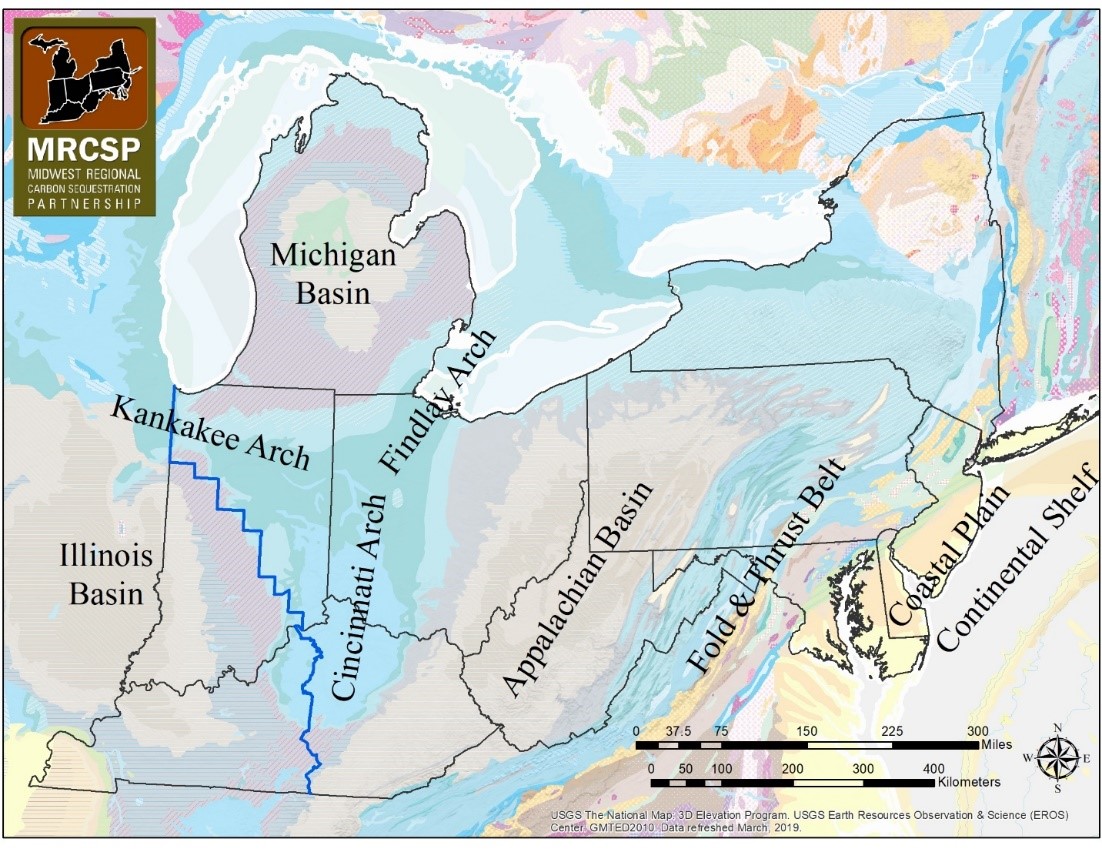

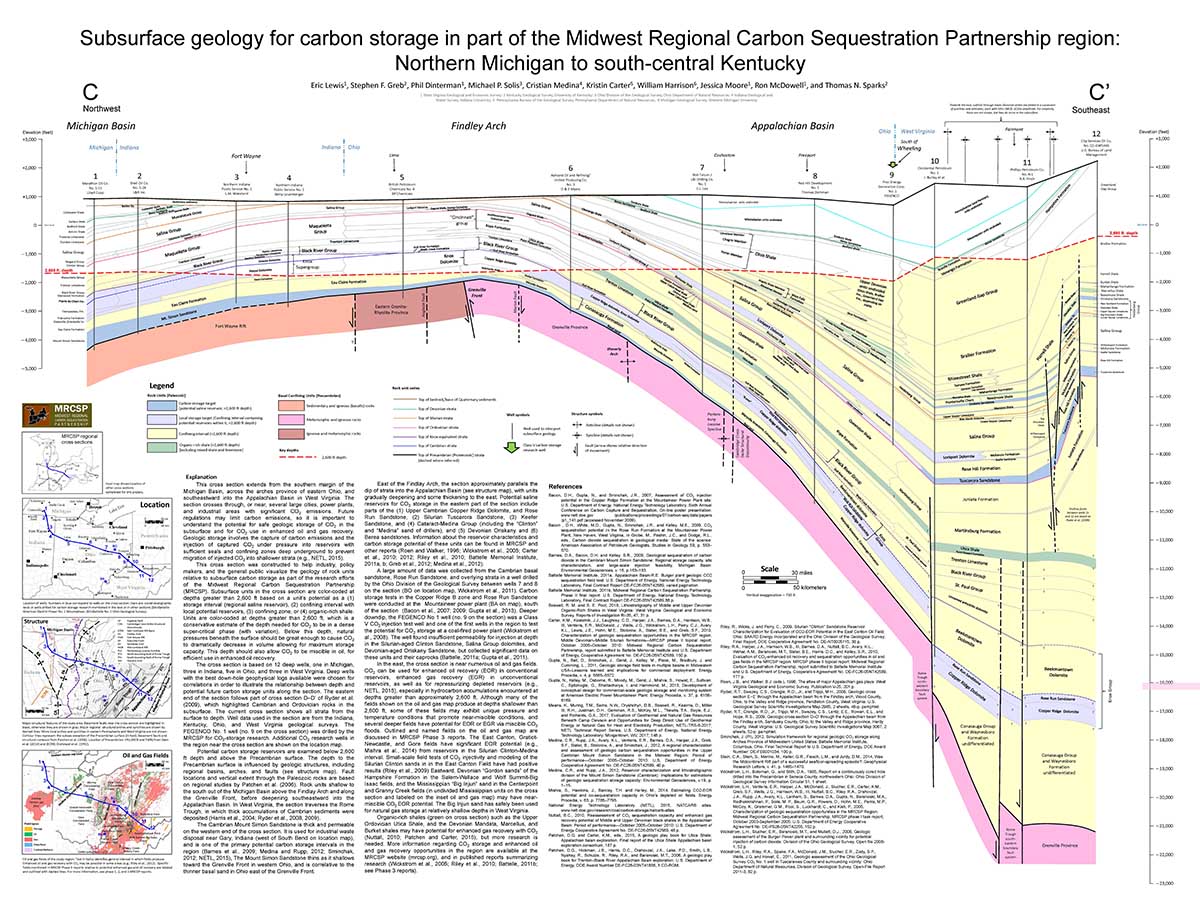

The Midwest Regional Carbon Sequestration Partnership (MRCSP) built an active collaboration with the Regional Geological Surveys and Universities (the MRCSP GeoTeam) that continued regional assessments in parallel with the large-scale test. The regional work spans Michigan and Appalachian basins, Arches province, Coastal Plains, and offshore regions, with a focus on selected topics such as description of carbon dioxide (CO2)-enhanced oil recovery (EOR) opportunities, onshore and offshore storage assessments along the Atlantic Coast, and storage resources in key rock formations across the MRCSP region. The GeoTeam produced multiple reports, regional geologic cross-sections and maps, a composite database of petroleum fields, and a resource estimates database, while also acting as a technical resource for the stakeholders within the 10-state region. The regional geologic cross-sections depict CO2 storage intervals, caprocks, and geologic structures across key areas of the MRCSP region:

- The Appalachian Basin enhanced recovery opportunities task defined parameters for CO2-EOR in MRCSP oil and gas fields, assessed CO2 storage in MRCSP organic-rich shales, and detailed potential CO2-EOR fields in the Ohio-Pennsylvania-West Virginia tri-state area.

- The Michigan Basin task examined Silurian-age pinnacle reefs in terms of their use for CO2-EOR.

- The Mid-Atlantic Coastal Plain and adjacent offshore region task characterized carbon storage in the eastern portion of the MRCSP region based on log analysis, formation maps, and sequence stratigraphy.

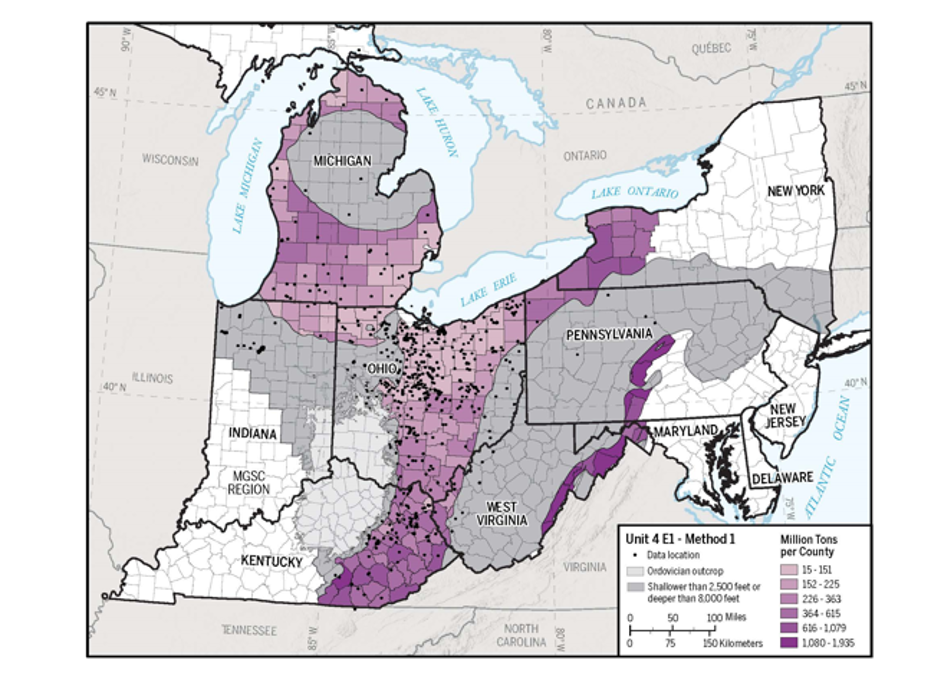

- The Ordovician-Cambrian Units task applied several different resource calculation methods for key deep rock layers in the Michigan Basin, Cincinnati Arch, and Appalachian Basin.

- The Upper Silurian to Middle Devonian task examined storage in Ohio based on stratigraphy, formation maps, and structural features.

- The Triassic Rift Basins task assessed CO2 storage potential in the Taylorsville Basin, Culpeper Basin, Gettysburg Basin, and Triassic mafic igneous rocks in the Maryland, New Jersey, and Delaware region.

Together, the regional characterization effort developed useful products to support project developers, policy makers, and other stakeholders in the MRCSP region seeking to understand where potential storage exists relative to large stationary sources of CO2 emissions.

Story of Interest

A program like the Midwest Regional Carbon Sequestration Partnership (MRCSP), conducted over 17 years, must be both technically resilient and flexible to adjust and adapt to changing economic, policy, and technology conditions over time. Management of complex, long-term research and development (R&D) programs with a government-industry interface has numerous facets, any of which can impact the ultimate success. In this regard, it is very important to develop and follow collaborative processes to ensure successful completion of projects. Some of the changes MRCSP faced during the project include:

- Growth in Enhanced Oil Recovery (EOR) Fields Over Time: MRCSP Phase III was conducted in an actively growing complex of small oil fields owned and operated by Core Energy. The addition of new oil fields offered a chance to customize the research based on the individual field geology, layout, and observations from the preceding fields. This customized approach required planning to preserve budget for newly identified technical efforts, as well as technical flexibility to adjust the priorities.

- Changes in Site (Having Plan A, B, and C): Program success depends on being able to make major changes in response to unforeseen conditions. For the MRCSP Phase III, the initial proposed location was at an ethanol plant, directly above a suitable storage reservoir. However, due to possibility of delays resulting from public concerns, an early decision was made to move to another saline reservoir site with carbon dioxide (CO2) from gas processing. Even at this site, the U.S. Environmental Protection Agency’s (EPA) new requirements for Class VI wells added project unmitigated risks. Once again, the program was shifted to evaluate CO2 storage in depleted oil fields including CO2-EOR, permitted under Class II injection well protocols. This highlights the need for having multiple back-up options.

- Changes in Regulatory Landscape: During the MRCSP program, there were multiple changes in the regulatory environment. On a federal level, the overall policy on climate change shifted based on the political priorities, affecting stakeholder interest. The emphasis within the U.S. Department of Energy (DOE) moved between saline storage and EOR over time. Finally, the EPA regulations for CO2 injection evolved from Class V experimental well status to more stringent Class VI wells with related post-injection monitoring requirement. The availability of the Core Energy EOR assets in the same area allowed the program to promptly shift focus to potential EOR opportunities, thereby mitigating the impact of regulatory changes on the program.

- Changes in Market Conditions (i.e., Oil Prices, Field Services): Fieldwork-intensive programs, such as MRCSP, can be strongly impacted by the oil prices, which fluctuated between $30 to more than $110 per barrel. While low prices can reduce oil field services costs, they can also make it difficult for the host site to continue operations or invest in new facilities. High oil prices can significantly increase services cost and availability, at the same time offering new research opportunities in an expanding operational context. Because the overall project budget is fixed, the program must be able to absorb these fluctuations.

- Change in Project Staff and Leadership: Over its duration, MRCSP worked through changes of five DOE Project Managers (PMs), at least five Battelle PMs, several project controls analysts, and senior technical staff, in most cases with sufficient notice to allow for orderly transition and transfer of knowledge. The impact of sudden departure of key staff can be disruptive, but can be mitigated by using a team approach, with the deputies and leadership team fully informed of status and key issues.

Research vs. Commercial

The Midwest Regional Carbon Sequestration Partnership (MRCSP) Phase III test was effectively conducted in a commercial carbon dioxide (CO2)-enhanced oil recovery (EOR) setting and several aspects were the same as they would be in a commercial carbon capture, utilization, and storage (CCUS) project, where associated CO2 storage is used to demonstrate storage and containment under the U.S. Environmental Protection Agency’s (EPA) Class II injection well permits and Subpart RR of the Greenhouse Gas Reporting Rules for tax credits. The MRCSP accounting and storage methodology was used to develop the monitoring, reporting, and verification (MRV) plan.

A significant amount of research on reservoir characterization, modeling, and monitoring technologies to prove the effectiveness of storage, containment, and technology readiness was conducted during the MRCSP Phase III work. Only a subset of these investigated technologies may be needed for commercial CO2-EOR/storage deployment. In addition, MRCSP tests relied on, and in some ways were constrained by, existing infrastructure and operational parameters, whereas a new commercial project would not need to adhere to this preexisting framework. Finally, while many findings are relevant to saline reservoir storage, the permitting (Class VI wells), characterization, well design, monitoring, and legal requirements for commercial storage-only projects would be different than this project experience. A commercial project may also have more limited flexibility of time, expense, and operational changes than were possible with the MRCSP research project.

Tech Transfer

Technology transfer was a key aspect of the Midwest Regional Carbon Sequestration Partnership’s (MRCSP) work. The MRCSP team has conducted or participated in numerous workshops, technical conferences, stakeholder outreach open houses, and industry meetings for carbon capture, utilization, and storage (CCUS) and environmental applications. MRCSP has also published many peer-reviewed and proceeding papers. Some examples of technology transfer include:

- MRCSP Partners and GeoTeam Meetings: Held annually at various venues (Columbus, Ohio; Washington, D.C.; Baltimore, Maryland; Annapolis, Maryland; and Traverse City, Michigan), these attracted up to 100 participants where the MRCSP team presented latest research findings and held panel discussions, and status updates were provided from invited speakers. The meetings were combined with the field trips, regional geology team meetings, and topical workshops.

- Hosting Workshops and Visitors: The most prominent event was the International Energy Agency (IEA) Greenhouse Gas Research and Development (R&D) Programme (IEAGHG) Monitoring Group Workshop in 2017, which attracted approximately 80 international visitors. Several other delegations visited the Michigan site to learn about carbon dioxide (CO2)-enhanced oil recovery (EOR) and utilization.

- Conferences and Workshop Presentations: MRCSP work was presented at every Greenhouse Gas Control Technologies (GHGT) meeting since 2004; national CCUS conferences; U.S. Department of Energy (DOE) annual meetings; Society of Petroleum Engineers (SPE), American Association of Petroleum Geologists (AAPG), and American Institute of Chemical Engineers (AIChE) meetings; IEAGHG and IEA workshops; Carbon Sequestration Leadership Forum (CSLF) workshops; North American Energy Ministers Trilateral Carbon Capture and Storage (CCS) Group meetings; U.S.-Japan Bilateral CCS meetings; Petroleum Technology Transfer Council; and more.

- Peer-Reviewed and Conference Papers: Covering various topics, from project management to technical findings, at both international and domestic venues.

- Science, Technology, Engineering, and Math (STEM) Outreach: For children and young adults, which involved planning and running experiments with the American Association of University Women (AAUW) in Gaylord, Michigan, and the Be WISE STEM Camp in central Ohio.

- MRCSP Website (www.MRCSP.org): The website was used to share latest information with the stakeholders, including updates on field work, sharing of published reports, updated CO2 injection amounts, and a “What’s New” section.

- DOE Best Practices Manuals: MRCSP contributed to all of the DOE Best Practices Manuals for CO2 storage.

- Technical Exchange: MRCSP participated in technical exchange with other projects, such as the Hontomin Technology Development Plant (TDP) for CO2 geological storage in Europe, and collaborated on technical presentations with a storage project in Spain in carbonate rocks.

Partners

Phase III Injection Test Host Site

- Core Energy, LLC (Otsego County, Michigan, USA)

Geologic Surveys and Universities (regional geologic research team)

- Indiana Geological and Water Survey at Indiana University

- Kentucky Geological Survey at University of Kentucky

- Maryland Geological Survey

- Division of Geological Survey at Ohio Department of Natural Resources

- The Ohio State University

- Pennsylvania Geological Survey

- Rutgers University

- West Virginia Geological and Economic Survey

- Michigan Geological Repository for Research and Education at Western Michigan University

- Delaware Geological Survey at University of Delaware

- New York State Museum

Industrial and Other Partners During Phase III (Note: Some companies have changed names or disappeared over time.)

- American Electric Power (AEP)

- AMP Ohio

- Arcelor Mittal

- Babcock and Wilcox

- BP

- CONSOL Energy

- Constellation Energy Group

- Consumers Energy

- Dominion

- DTE Energy

- Duke Energy

- First Energy

- Indiana Office of Utility Consumer Counselor

- National Rural Electric Cooperative Association (NRECA)

- New York State Energy Research and Development Authority

- New York State Museum

- NiSource

- Office of the Ohio Consumers Council

- Ohio Coal Development Office

- Ohio Environmental Council

- Pacific Northwest National Laboratory

- Paulsson, Inc.

- Praxair

- RWE (Germany)

- Schlumberger

- Sinotech (Taiwan)

- The Keystone Center

- Wade Consulting