Advanced Turbines

Developing advanced turbine technologies in pursuit of power generation with higher efficiency, flexibility, and lower costs

The National Energy Technology Laboratory (NETL) Advanced Turbines Program is developing innovative advanced turbine technologies to enable higher efficiency and fuel flexibility with the goal of producing reliable, affordable, and diverse energy supplies, supporting U.S. energy dominance.

Explore Key Technology Areas

Program Area

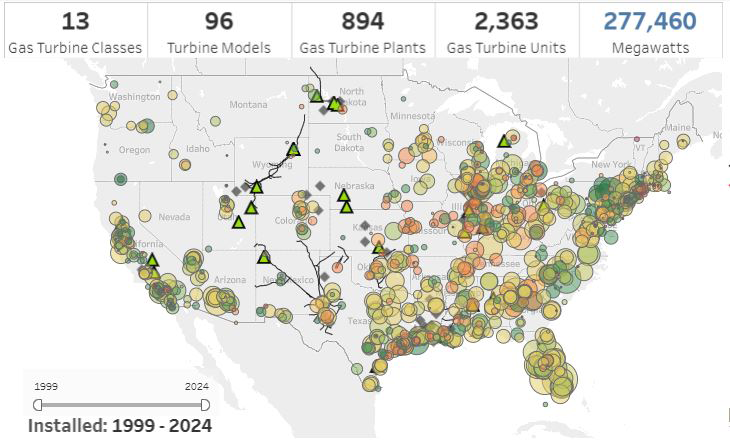

USA Gas Turbine Fleet

Legacy power plant units (1998 or earlier) are generally excluded. Emissions data is estimated based on an empirical relation using turbine class or turbine inlet temperature when known. Turbine operational data is gathered from the Energy Information Administration (EIA) monthly reports (EIA-860 and EIA-923) as well as independent public resources.

Additional Resources

NETL implements this effort as part of DOE’s Hydrogen with Carbon Management Program.