Computational Science and Engineering

Pioneering simulation models and machine learning to accelerate American energy innovation.

NETL's Computational Science and Engineering (CSE) directorate pioneers and applies science-based simulation models, mathematical methods and algorithms, scientific machine learning and software tools to address technical barriers and develop next-generation energy technologies. Our CSE capabilities leverage four focus areas — computational materials engineering, computational multiphase flow science, advanced scientific computing and data science — to drive American energy innovation.

Supported by world-class expertise and facilities, NETL's simulation-based engineering accelerates the development of novel energy materials, processes and device designs, using sophisticated tools like MFiX multiphase flow modeling and the Energy Data eXchange® (EDX®) virtual data curation and collaboration platform. Our computational science work increases resource recovery rates, optimizes energy system performance, reduces development time for new materials and expedites decision-making.

Recent Publications

Computational Science and Engineering

Advanced Scientific Computing

NETL’s Advanced Scientific Computing work accelerates energy innovation and data science through on-site and cloud-based computational infrastructure tailored to research needs, including NETL’s Science-based Artificial Intelligence and Machine Learning Institute (SAMI). We implement new mathematical and computer science methods that demonstrate power-efficient, extreme-speed scientific simulation with emerging wafer scale computer and quantum computing architectures. We also develop visual analytic methods that help reduce risk and costs for complex system R&D and implement graph-based data platforms that increase our ability to extract key actionable information deeply embedded in diverse data sets. Together, these tools help our experts and research partners collect and analyze vast amounts of data, communicate the results, and unlock new insights.

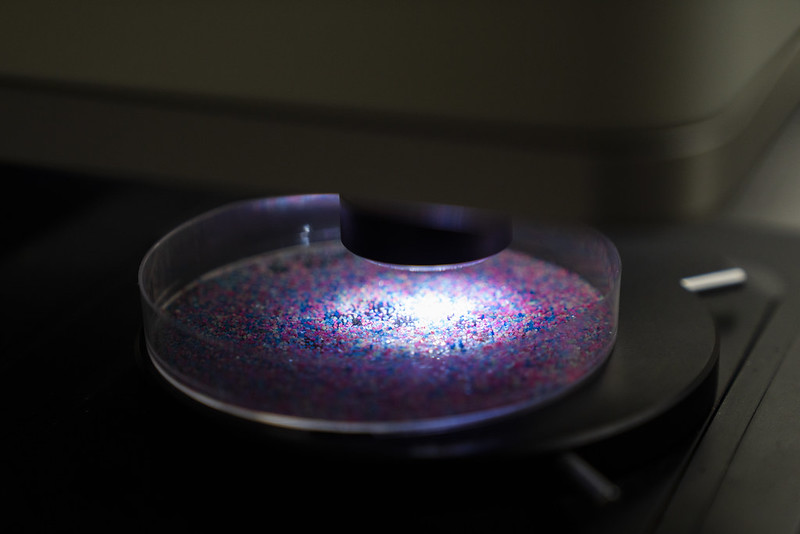

Computational Materials Engineering

NETL’s Computational Materials Engineering expertise in physics- and AI-driven materials modeling at atomic, molecular and microstructural scales provides a fundamental understanding of materials characteristics and behavior. We use data-driven insights to design optimized materials with specific attributes for energy applications, including catalysts and electrocatalysts, oxygen carrier materials, structured materials and novel nanostructured materials for energy conversion and gas sensors.

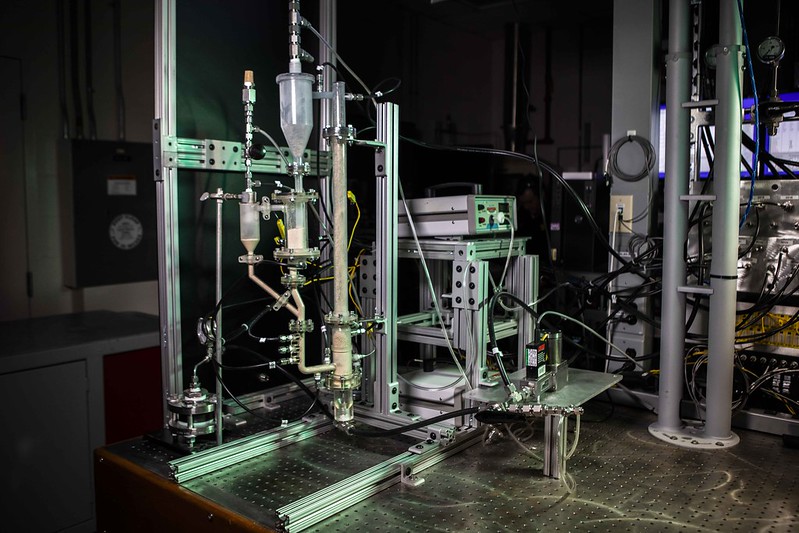

Computational Multiphase Flow Science

NETL's Computational Multiphase Flow Science work provides national laboratory expertise through computational and experimental R&D complemented by high-performance computing. Our portfolio features the MFiX suite, an open-source, physics-based computational fluid dynamics (CFD) multiphase flow software for designing, optimizing and scaling up advanced multiphase reactors for energy and chemical production technologies. MFiX-Exa is an exascale open-source software solution that further accelerates reactor design and scale-up.

Key Physical and Virtual Facilities

NETL is harnessing the power of the world’s largest computer chip — the wafer scale computer — a miniaturized and optimized supercomputer on a single giant silicon wafer, enabling power-efficient, extreme-speed scientific simulations.

This innovation helps scientists and engineers run high-fidelity simulations hundreds of times faster and with far less energy than typical supercomputers, modeling complex energy systems and optimizing performance.

The wafer scale computer helps achieve breakthroughs in:

- Computational fluid dynamics, scientific computing and grid challenges

- Developing the world's first computational fluid dynamics simulation run on the platform

- Extending high-bandwidth, low-latency communications

- Solving distributed memory problems

- Advancing research in electrodynamics, geomechanics, structural mechanics and other areas

NETL's technical capabilities in multi-scale modeling and simulations enable researchers to predict material properties and behavior in extreme conditions, demonstrating expertise in density functional theory; molecular dynamics; and physics-informed, multi-objective machine learning.

These simulations help researchers and manufacturers design and optimize cost-effective materials by accelerating the development process and improving manufacturing efficiency, resulting in enhanced performance, reduced costs and increased safety.

NETL's equipment and tools have many uses, including:

- Molecular dynamics and phase field simulations

- Turbine development, pressure vessel design, oil and gas transportation and other applications

NETL’s MFiX-Exa code leverages high-performance computing for multiphase flow simulations, including developing and applying advanced numerical methods and models to simulate complex systems.

This tool helps researchers who strive to model and analyze multiphase flows by solving complex equations and reducing computational time with significantly improved accuracy and efficiency. This enables a deeper understanding of energy systems that minimizes risk and accelerates the deployment of emerging technologies.

MFiX-Exa supports multiple particle models and can be used to model:

- Chemical reactions

- Heat transfer

- Mass transfer in complex systems

- Other technologies and energy systems

SAMI uses artificial intelligence (AI), machine learning (ML), data analytics and high-performance computing to accelerate breakthroughs for efficient, affordable energy production and utilization, materials, infrastructure and more.

This institute helps NETL partners who are working to pioneer next-generation AI tools in modeling for transformational energy technologies; smart data platforms for better data interpretation; predicting energy consumption patterns more accurately; and other scenarios, such as offshore modeling for operations and infrastructure longevity.

SAMI leverages NETL’s cutting-edge computational infrastructure, including:

- Joule 3.0 supercomputer

- WATT graphics processing unit-based cluster

- EDX®

SAMI is also fostering partnerships for AI adoption and supporting AI workforce development.

.jpg)

.gif)