Gas Turbine Fleet Data Map Methodology

Primary Sources for Current Turbine Installations

The NETL turbine installation map tool generally covers new turbine installations from 1999 to 2024. The primary source of info for these turbines is the EIA’s monthly 860 report’s generator level data and 923 report’s electricity generation data (up to December 2024). Additional installations were added based on information from the 2024 Gas Turbine World Handbook. Entries were organized based on the EIA’s Plant ID and Generator ID for unique identifiers. Entries from sources other than the EIA were given unique identifiers based on the primary source of the data. For convenience, only turbines within the continental U.S., Hawaii, and Alaska were considered (i.e., no offshore units and no units in U.S. territories or other countries).

Primary Sources for Existing CO2 and H2 Management Infrastructure

Other items available on the map include available Class VI CO2 storage wells, CO2 and H2, pipelines, and other hydrogen infrastructure/hubs. For the Class VI wells, the EPA keeps an active record of all Class VI well applications available to the public. Both a Map and a complete list of applications under review were used to determine the approximate locations of available Class VI wells for the NETL’s map. For the CO2 pipeline and hydrogen data, a number of sources were consulted. Hydrogen pipelines locations were found from a report from the Congressional Research Service. This information was cross-referenced with information from the National Renewable Energy Laboratory’s (NREL’s) Hydrogen Demand and Resource Analysis (HYDRA) Tool. More information about this tool can be found here. CO2 pipeline locations were gathered from another interactive map from the Pipeline and Hazardous Materials Safety Administration (PHMSA). Finally, all of the above information was cross-referenced with NETL’s in-house EDX Carbon Management Projects (CONNECT) Sandbox, located here. The EDX database also contains data maintained by NETL about hydrogen hubs, carbon capture projects, and other relevant infrastructure.

Data Validation and Source Supremacy

The EIA data mentioned above was generally taken to be the original source for installations. Plants whose existence and/or completion status could not be verified and plants that were confirmed to have been demolished or cancelled were ignored for the purpose of generating the dataset. As the EIA does not have information on the gas turbine firing class or operating data, such information was taken from either Gas Turbine World or an independent source (see below).

To ensure the accuracy of the dataset, all entries (plus some tentative projects that are still under construction) were cross-referenced with information from the Power Technology database and the Global Energy Monitor Wiki. In cases where the original EIA data is directly in question, GEM Wiki was not used in order to avoid circular reference issues (GEM Wiki’s primary source of info often comes from past EIA reports). In cases where discrepancies were found between these primary sources, information from independent sources (provided for each entry where appropriate in the Tableau engine and accompanying spreadsheet) was used instead. (For example, the EIA entry “Jack McDonough,” with plant ID 710 – the actual name of the plant as recorded by the owners is the “McDonough-Atkinson Power Plant,” so this is the name used for the map tool. Another example: Brea Power II, LLC’s plant, with plant ID 58007 – the EIA lists this as the “Brea Expansion Plant.” This is part of the “Brea Power Project,” and it is a unit installed at the Olinda-Alpha Landfill. Thus, “Olinda-Alpha Landfill” is the name used. Other items, such as owner re-brandings, transfers of ownership, and other such recent changes not captured by the EIA were noted and changes were made appropriately as discovered). In general, any information taken from independent sources, especially turbine OEMs and plant owners, is treated as the most accurate. Turbine spec and operability data is gathered from Gas Turbine World and verified in a similar fashion with spec data from OEMs where available. Plant location data was taken from coordinates provided by the EIA and verified using Google Maps.

Carbon Dioxide Emissions Calculations

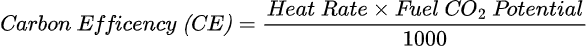

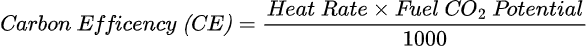

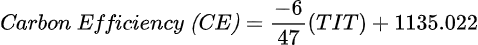

The primary method of determining the overall CO2 emissions of any given engine is based on the calculation of the engine’s “Carbon Efficiency” (CE). The CE values were calculated based on the OEM-specified heat rate (in Btu/kWh, calculated based on LHV) and fuel CO2 potential (in lb CO2/MMBtu), as described in Equation 2.

Eq. 1

Here, the conversion factor of 1,000 is used to convert the units in the denominator from MMBtu to Btu by dividing by 1 million and from kWh to MWh by multiplying by 1 thousand (1,000/1,000,000 = 1/1,000). This yields the unit-specific carbon efficiency in terms of lb CO2/MWh. This method is representative of real engines operating under ISO conditions. In most cases, the fuel CO2 potential was taken from the EIA (where it is referred to as Carbon Dioxide Emissions Coefficient). For syngas and landfill gas, the CO2 potential was calculated based on a representative blend of gases based on several past published datasets as an overall “average.” For syngas, the representative blend chosen was 33% H2, 16% CO2, 45% CO, 2% CH4, and 4% non-fuel gases by volume. For biogas/landfill gas, a blend of 50% CH4, 45% CO2, and 5% N2 was used. From these blends, the CO2 potential can be calculated based on the stoichiometric combustion of the gas blends under standard conditions assuming that the volume percentages are analogous to molar percentages (ideal gas assumption). For any nondescript gas with no representative or standardized composition, this method cannot be used.

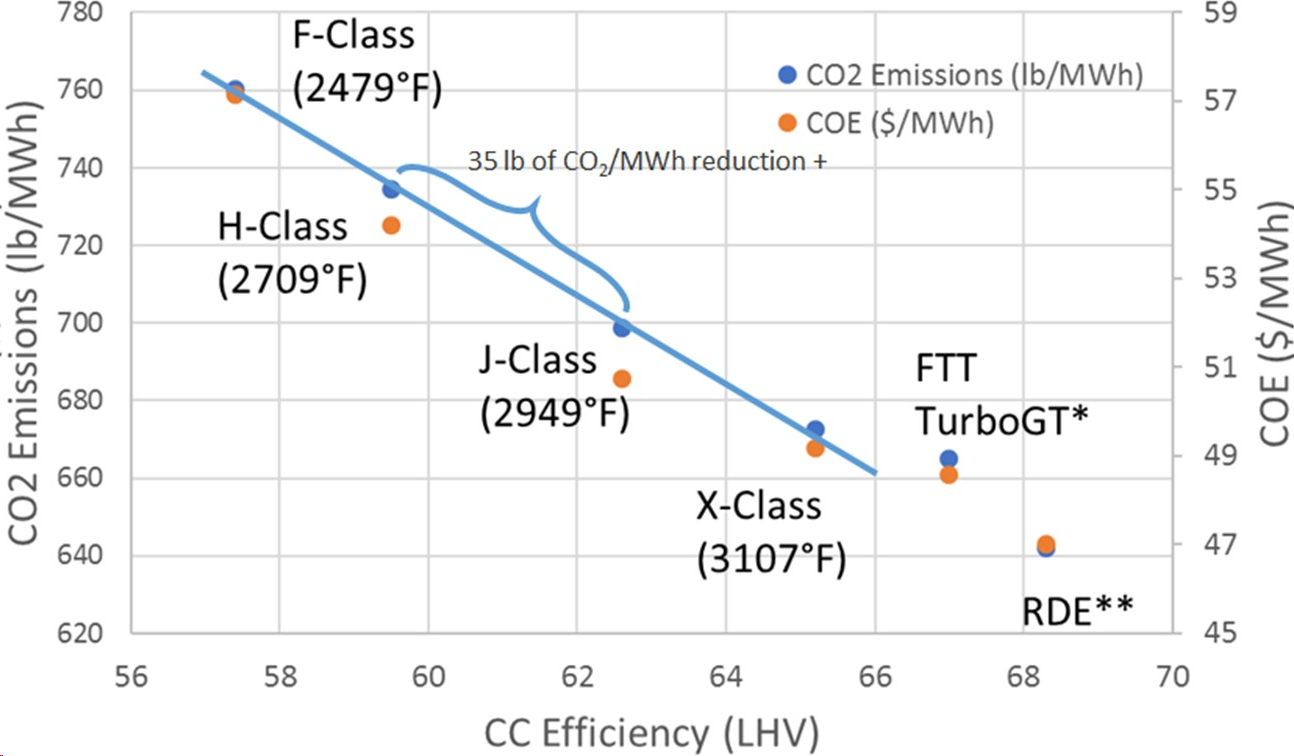

In the case that there is no heat rate data available or an incompatible fuel is used, NETL has access to empirical data gathered from decades of gas turbine testing data from OEMs, which is summarized below in Figure 1.

Figure 1 Turbine emissions correlated with turbine inlet temperature

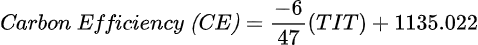

From this chart, it is possible to generate an equation for the CE using a linear approximation, as shown in Equation 2.

Eq. 2

where the Turbine Inlet Temperature (TIT) is in °R (degrees Rankine), yielding a number roughly between 650 and 800 lbs/MWh., which is somewhat more optimistic than the heat rate data calculation, which typically yields CEs in the 900-1200 lbs/MWh range.

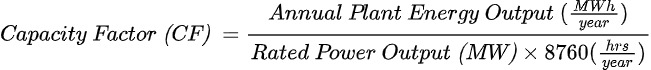

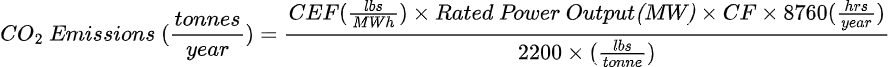

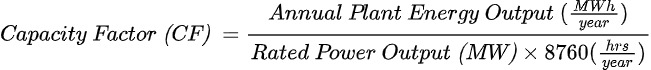

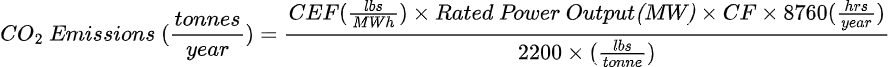

Based on the CE and the capacity factor (CF, defined as the actual annual energy output compared to the maximum possible annual energy output assuming 100% full load operation year-round), the total emissions can be estimated, via equations 3 and 4:

Eq. 3

Eq. 4

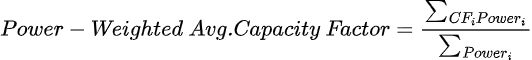

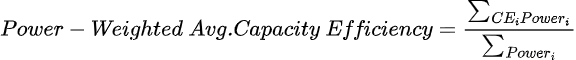

The capacity factor was calculated using the monthly energy output information from the EIA-923 report. In cases where this data was not available, plant-level data from the same EIA-923 report was used to determine an overall plant capacity factor and accompanying plant month-by-month energy graph. In cases where none of this data was available, a rough estimate of 85% capacity factor is assumed. For the plant-level CE vs CF graph, both variables are calculated at the plant level by averaging the CE and CF values of individual units where available and weighting the terms by power output, as shown in Equations 5 and 6.

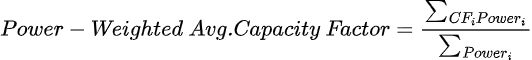

Eq. 5

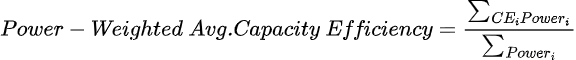

Eq. 6

For the CO2 emissions, in cases where the CE could not be estimated due to lack of information on the TIT, a TIT was assigned based on the firing class, determined by Fig. 1. In all other cases, no calculations were made, and the CO2 emissions calculation process was skipped. For extremely small turbines (such as micro turbines), no calculations were made, as these were considered to be too far outside of the available data range to accurately predict the emissions via the aforementioned linear estimation scheme.

In some specific cases, the EIA dataset has information on plant-level energy output but not unit (turbine)-level energy output. In these cases, this plant-level data was used in the plots on the main map to show the month-by-month plant energy outputs for key plants where unit-level data is absent. Due to compatibility issues, this data was not used for the aggregated capacity factor plots on the dashboard: plants with no unit-level data available were thus omitted from these plots.

Update Procedure

This dataset will be updated yearly based on new information from the EIA as it is created. New entries will be added based on the previously mentioned methodology. As new information becomes available for individual plants/installations, those entries will be updated with the most current information available. Any entries that cannot be verified via one of the aforementioned independent sources (including plant owners and independent news sources) will be ignored.

Advanced Turbines Home

Advanced Turbines Home

Advanced Turbines Home

Advanced Turbines Home